24

24

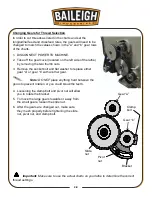

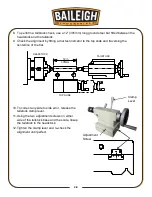

Four Jaw Chuck Installation Preparation

1. With the 3-jaw chuck removed, take note of how far the

camlock studs protrude from the back face of the chuck and

note the dimensions.

2. Thread each of the 4-jaw camlock studs into the back of the

4-jaw chuck using the dimension obtained from step 1.

Screw in the locking capscrews that keep the studs from

coming out.

3. Lay a piece of plywood on the lathe bed directly beneath the

spindle housing. This will help protect the ways if the chuck

should fall.

4. Lift the chuck up to the spindle and insert the camlock pins

into the face of the spindle.

5. While supporting the weight of the chuck, use the chuck key

to turn one of the cams until the cam line is between the two “V” marks on

the spindle.

6. Rotate the spindle and repeat step 3 for the rest of the cams.

7. Starting with the first cam, snug up the cams.

8. Finally, recheck and fully tighten all of the cams.

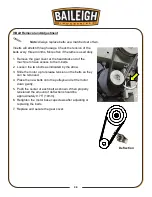

Faceplate Installation Preparation

1. With the 3-jaw chuck removed, take note of how far the

camlock studs protrude from the back face of the chuck

and note the dimensions.

2. Thread each of the faceplate camlock studs into the back

of the faceplate using the dimension obtained from step 1.

Screw in the locking capscrews that keep the studs from

coming out.

3. Lay a piece of plywood on the lathe bed directly beneath

the spindle housing This will help protect the ways if the

faceplate should fall.

4. Lift the chuck up to the spindle and insert the camlock pins

into the face of the spindle.

5. While supporting the weight of the faceplate, use the chuck key to turn

one of the cams until the cam line is between the two “V” marks on the

spindle.

6. Rotate the spindle and repeat step 3 for the rest of the cams.

Summary of Contents for PL-1340E-1.0

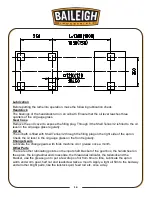

Page 48: ...45 45 ELECTRICAL DIAGRAM...