36

36

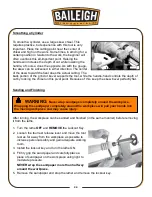

MAINTENANCE

Maintenance on your lathe should be done at periodic intervals to ensure that the machine is in

good working order. Inspection and maintenance should be performed at least twice a year but

more often if the lathe receives constant use.

•

Check daily for any unsafe conditions and fix immediately.

•

Check that all nuts and bolts are properly tightened.

•

On a weekly basis clean the machine and the area around it.

•

Lubricate threaded components and sliding devices.

•

Apply rust inhibitive lubricant to all non-painted surfaces.

Note: Proper maintenance can increase the life expectancy of your machine.

•

Check all fasteners to make sure they are tight and check all adjustments that they are in

order.

•

Clean and oil the lathe beds so that the headstock, tailstock and tool support base will

slide easily. Clean any rust spots that may develop on the bed with a commercial rust

remover.

•

Use compressed air to blow out the interior of the headstock in order to keep chips and

sawdust from accumulating on the belts and pulleys.

•

Clean out the Morse tapers on both the headstock and tailstock. Commercially available

cleaners may be acquired form local tool stores.

•

Check the drive belt for tightness. It should be snug but not overly tight.

•

Use a mill file to remove any nicks or dings from the tool rests.

•

Clean and lubricate the tailstock ram and locking mechanism.

WARNING:

Make sure the electrical disconnect is OFF before working on

the machine.

Maintenance should be performed on a regular basis by qualified personnel.

Always follow proper safety precautions when working on or around any machinery.

Summary of Contents for WL-1218VS

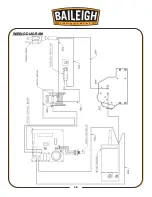

Page 41: ...38 38 WIRING DIAGRAM ...

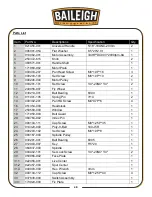

Page 42: ...39 39 LATHE PARTS DIAGRAM ...

Page 49: ...46 46 NOTES ...

Page 50: ...47 47 NOTES ...

Page 51: ...48 48 NOTES ...