33

33

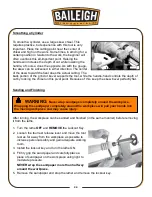

3. The tool is held well up on the work, with the

bevel or grind tangent to the revolving surface.

This position will give a clean shearing cut.

When pushed straight into the work, the gouge

has a scraping action, (normally a poor practice

in spindle turning). The roughing cut is

continued until the work approaches 1/8” of the

required diameter. Once a cylindrical form has

been obtained, the turning speed can be moved to the second or third speed setting.

Note: Continue to move the tool rest inward toward the work piece to keep the

safe distance between the two.

Position of Hands

While turning, the hand that holds the tool handle

should be in a natural position. This hand provides the

leverage for the tool by either moving in toward the

chisel or moving out. The position of the tool rest hand

is more a matter of individual preference, rather than a

“set” or “proper” position. However, a palm-up grip is

generally considered best. In this position, the first

finger acts as a guide, sliding along the tool rest as the

cut is made.

The alternate position is a palm-down grip. In this

position, the heel of the hand or the little finger serves

as a guide. The palm-down position is solid and positive

– excellent for roughing or heavy cutting. Most

beginners start with the palm-down grip, switching later

to the palm-up position for better manipulation of the

chisel.

Summary of Contents for WL-1218VS

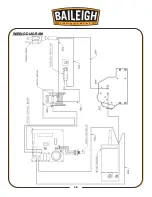

Page 41: ...38 38 WIRING DIAGRAM ...

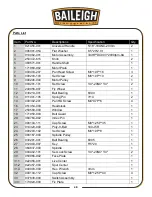

Page 42: ...39 39 LATHE PARTS DIAGRAM ...

Page 49: ...46 46 NOTES ...

Page 50: ...47 47 NOTES ...

Page 51: ...48 48 NOTES ...