16

16

OPERATION

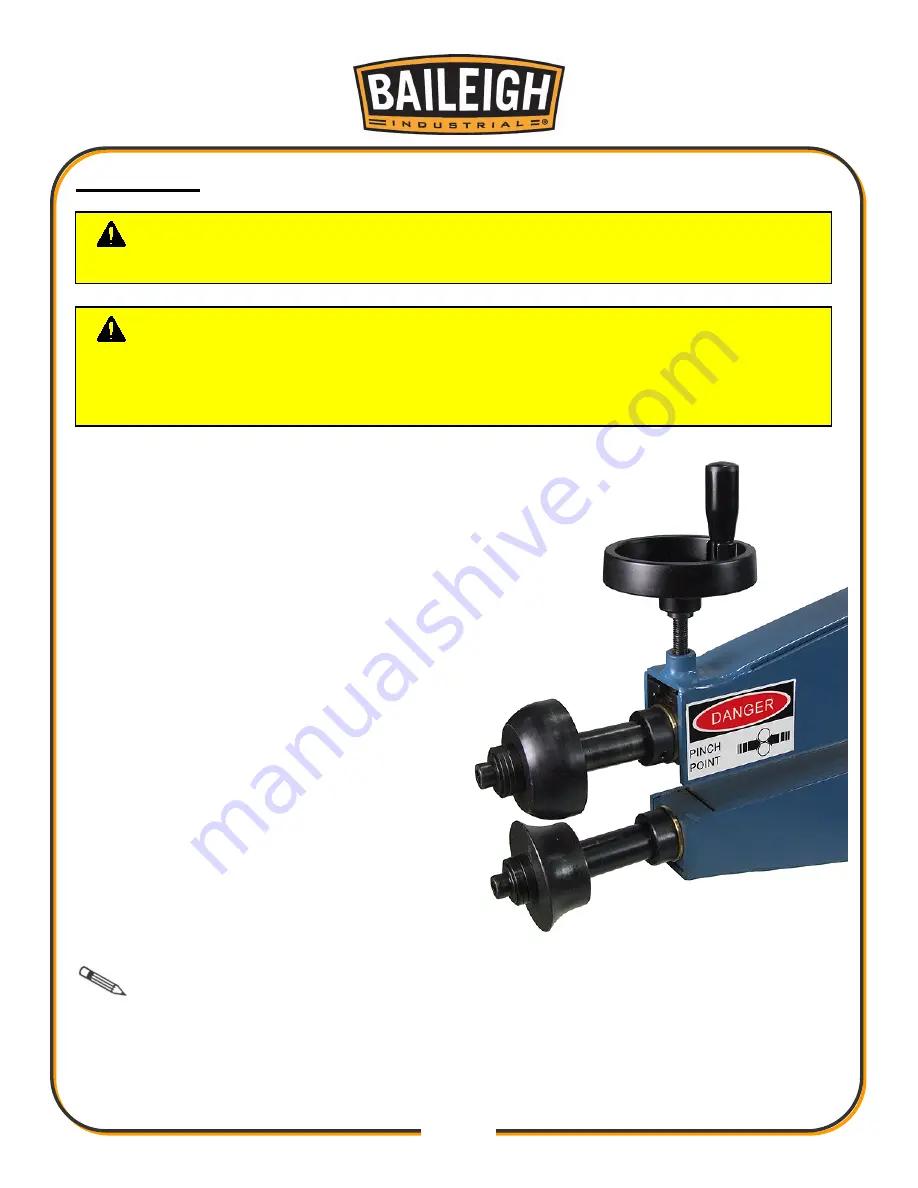

1. Select and install the die set required for the

desired bead type.

2. Use the handwheel to open the gap

between the roll dies large enough to insert

the material. Do not start with the rolls

completely closed as you may find that the

rolls are too close together and find it

difficult to feed the material.

3. Set the depth gauge as desired to assist in

positioning the material between the dies.

This also assists in repeatability.

4. When the material is positioned as desired,

closed the gap between the rolls to start to

impress the rolls into the material. This step

may require some experimentation to get

the proper depth so it is recommended that

you use a scrap piece of the same material

you want to bead roll.

Note:

Most beading operations will need to be done in several steps, increasing

the depth on each pass. Trying to bead too deep will flex the machine, so take your time with

multiple passes.

CAUTION:

Always wear proper eye protection with side shields, safety

footwear, and leather gloves to protect from burrs and sharp edges.

CAUTION:

Keep hands and fingers clear of the rolling dies. Be aware of

how the material moves as it is being formed. Normally the operator should stand in

front of the bead roller to avoid getting hit with the material as it is being formed.

When handling large heavy materials make sure they are properly supported.

Summary of Contents for BR-18M-24

Page 21: ...19 19 PARTS DIAGRAM A...

Page 22: ...20 20 PARTS DIAGRAM B...