Page 5

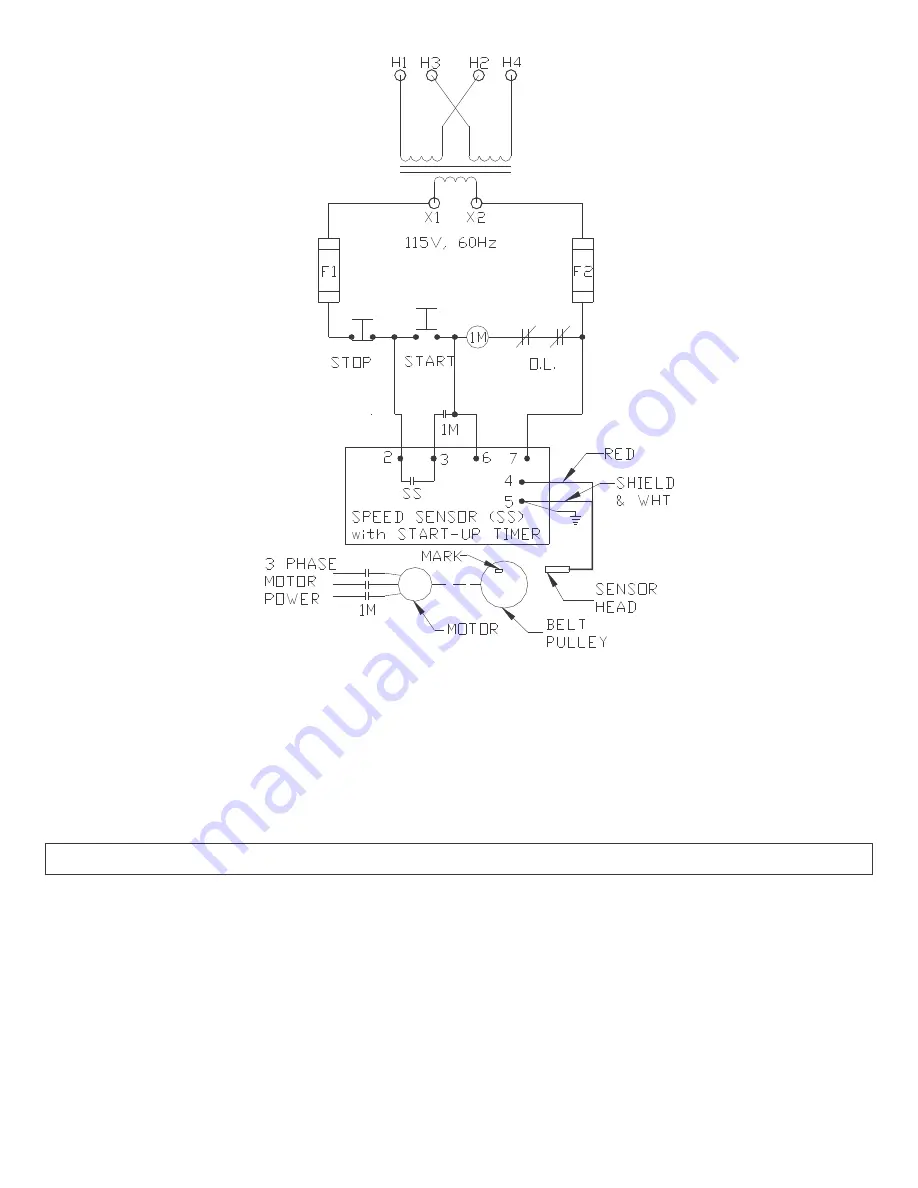

Figure 4 – Elementary Conveyor Control

Operating sequence:

1. Start button picks 1M coil and speed sensor.

2. 1M and SS contacts close to hold 1M and speed sensor.

3. Motor starts. If correct speed is reached before timeout, SS contacts remain closed ; otherwise SS opens, 1M drops, motor stops.

4. If speed sensor is set for underspeed detection and machine slows below setpoint, SS opens, 1M drops, and motor stops.

5. If speed sensor is set for overspeed detection and machine speed exceeds setpoint, SS opens, 1M drops, and motor stops.

6.0 OPERATION

6.1

Preliminary circuit tests.

If all connections are made as shown on the

connection diagram, above, the system should be

ready for power. To ensure proper wiring, perform a

visual inspection and ring-out before power is

applied for the first time.

6.2

Setup Procedure

If the speed sensor contacts are interlocking the

RUN circuit as shown in Figure 4, they should be

jumpered or bypassed until the sensor is set up.

Select the operating range by moving the J5 jumper

to the proper setting. Do not remove the J2 jumper

or move it from the “run” position as erratic

operation may occur.

6.2.1 Under Speed Detection

Move the J4 jumper to the lower (underspeed)

location. If startup delay is desired, rotate the

startup delay control to the desired time. Set the