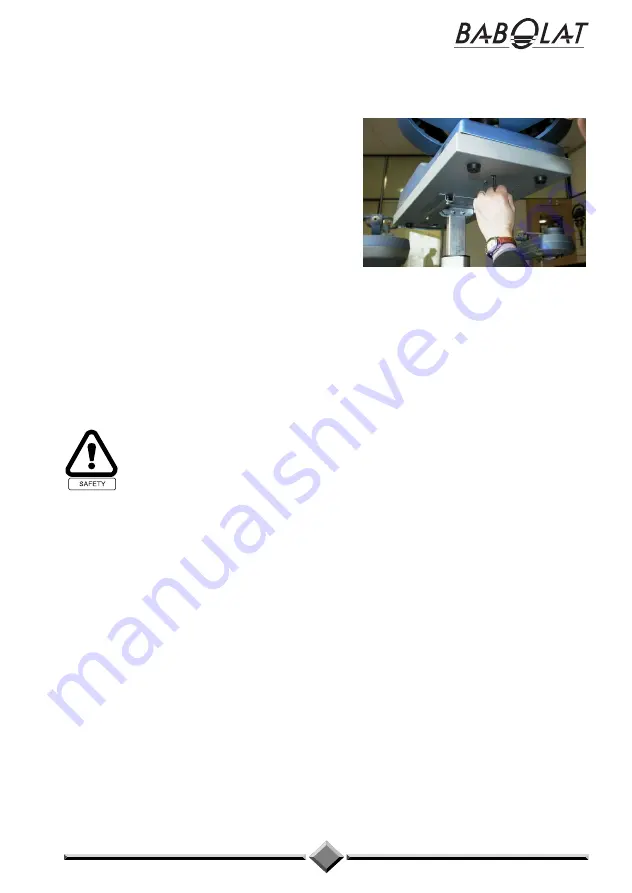

Rotate the turntable again by 120° to bring it

back to its initial position and lock the

rotating turntable by tightening the locking

button.

Lift up the turntable and remove it from its

central pivot.

Replace it with the new turntable, making

sure the interlocking elements are lined up.

For re-assembly, following the dismantling

procedure in the opposite order.

MAINTENANCE

Make sure the stringing machine is always turned off before cleaning

it or servicing one of its components. Unplug the power cable from

the mains socket.

Never wash the machine using water, a hose or high-pressure

cleaning.

BE CAREFUL:

never use corrosive products to clean your stringing machine.

Clean the housing of the machine regularly with alcohol at 90° only. Never use water,

detergents or acetone.

The circular turntable surface should be cleaned with alcohol every week to preserve the

optimal sliding capacities of the clamp-holder.

Remove the clamps, clean the clamp-holder rods and the inside of the clamp barrel with

a cloth soaked in alcohol, then lubricate them lightly with oil (sewing-machine type).

Replace the clamps on the clamp-holders and slide them about to spread the oil.

Clean the inside of the clamp teeth (depending on use, every day or once a week) with

a metallic brush, in order to avoid any clogging of the tungsten coating.

The Sensor pulling head does not require any particular servicing, apart from cleaning

once a year by passing a cloth soaked in alcohol between the articulated jaws of the

pulling unit.

Never oil the ball bearings on the pulling head.

27