13

HYDROCLIMA 2 - User Manual

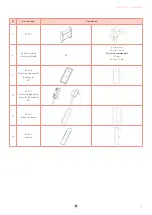

Gluing

1. Measure the heat sink installation points on the radiator according to “General installation rules”.

2. Before starting gluing degrease and clean the gluing area on the radiator.

3. Apply around 3 cm strips of Loctite AA 330 glue (yellow tube) on contact points between the heat sink and the

radiator (see image above).

6. Place the heat sink on the measured installation point and press for about a minute.

4. Apply the SF 7386 activator to the glue strips.

7. Place the allocator on the heat sink.

8. Close and secure the allocator with a seal at the bottom.

5. Apply the quick drying Loctite 454 glue (blue tube) in select spots (see image above) before the Loctite AA 330 glue

fully hardens and bonds with the activator (around 15 minutes).

CAUTION

: the glue bonding time can be longer if the radiator is cold

Summary of Contents for HYDROCLIMA 2

Page 1: ...v 1 0...