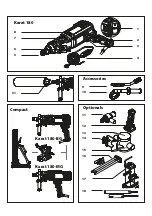

KARAT

®

180

US

OPERATING MANUAL KARAT® 180

9

Drilling

•

For wet drilling open the water valve

6

and

switch on the machine

2

.

•

Hold the machine as rigidly as possible.

•

Always use the grip

10

at the front of the

machine.

•

Start drilling by keeping the machine at a

slight angle. You can use the soft starter

3

at

drilling start.

•

After the bit is guiding itself into the material,

swivel back the machine into the right angle

position.

•

Drill using an even forward feed. Do not over-

load the machine.

•

The leaking water should be milky and not

clear.

•

After drilling switch the machine off and shut

off the water tap.

Hand held dry drilling

Using the dry drilling kit

•

Install dry drilling kit

11

on drill shaft

5

.

•

Mount the hose of an industrial dust

exhauster.

•

Drilling is only possible if the masonry is

absolutley dry

.

•

Use a powerful industrial dust exhauster.

Change the filter regularly, there is risk of

obstruction.

•

•

Hold the machine as rigidly as possible.

•

Always use the grip

10

at the front of the

machine.

•

Start drilling by keeping the machine at a

slight angle. You can use the soft starter

3

at

drilling start

•

After the bit is guiding itself into the material,

swivel back the machine into the right angle

position.

WARNING: The machine has a very

high torque, especially in the first

gear. Therefor drill only extremely

concentrated, especially when

working in first gear and with

diameters of more than 3”. In case

of sudden blocking of the core bit

the machine, despite the safety

clutch, might get out of control and

hurt you considerably.

DRILLING WITH A DRILL

STAND

Guide block setting

A

B

When using a drill stand a right setting of the

guide block is required. Guide blocks for Karat

core drilling machines features slide strips for fine

tuning on the drill stand.

•

Loosen the safety nuts

A

using the supplied

wrench 13.

•

Adjust the bolts

B

for an flexible sliding of the

guide block on the drill stand.

•

Secure then the bolts with the safety nuts

A

.

Drill stand fixation

CAUTION: The drill stand must

always be mounted firmly and

must not be able to move during

drilling.

Aligning the drill stand

•

Set up the drill stand at the drilling location.

•

Rotate the centering plate

28

forwards, until

it snaps in.

•

Align the drill stand in such a manner that

for the used machine the tip of the centering

plate is located directly above the required

drilling location.

•

Fasten the drill stand.

Secure using assembly

•

Drill the rawlplug hole Ø3/8” (see instruction

rawlplug).

•

Insert rawlplug 1/2” (M12).

•

Screw in assembly

30

.

•

Align the drill stand.

•

Fasten the drill stand with the spindle nut

29

.