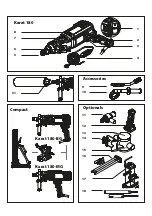

KARAT

®

180

US

10

OPERATING MANUAL KARAT® 180

Vacuum pump fixation

WARNING: Maximum drilling diam-

eter of 4”. Mount the drill stand on

an even, firm and smooth surface

using the vacuum pump, never

“over” head. Always connect the

core drill and the vacuum pump to

the same power outlet. Never turn

off the vacuum pump during oper-

ation.

Position the machine horizontally. Maximum tilt of

10°. Fasten, mount suction hose and fasten with

hose clip.

See further the vacuum pump manual.

Mounting the drill bit

•

Tighten the clamping lever

24

.

•

Clean and grease the thread on the drill bit

31

and the drilling shaft

5

.

•

Screw a core bit

31

onto the drilling shaft

5

and tighten with supplied wrenches.

Connecting the water feed

•

Close the water tap

6

.

•

Connect the water feed hose to the water tap

or the water pressure tank.

•

When using the water pressure tank, make

sure that there is sufficient pressure when

working.

•

Check the waterflow indicator

9

.

Setting the drilling angle

•

Loosen the clamping lever

21

.

•

Use handle

23

to slide the column into the

desired drilling angle using the scale.

•

Tighten the clamping lever

21

.

Drilling

•

Always ensure a adequate anchorage in the

underground.

•

Open the water tap

6

.

•

Loosen locking lever

24

and hold the feed

lever

20

.

•

Actuate the ON/OFF switch

2

.

•

You can use the soft starter

3

at drilling start

Drill using an even forward feed. Do not over-

load the machine.

•

The leaking water should be milky and not

clear.

•

Always loosen the locking lever

24

when

drilling.

•

After drilling switch off the machine and shut

off the water tap. Lift the machine with feed

lever

20

and secure with locking lever

24

.

Removing the drilling core

•

Break off the drilling core and remove.

OVER HEAD DRILLING

DANGER: When drilling “over” head

always secure the drill stand with

the assembly.

DANGER: When drilling “over”

head, always use a water collecting

ring and a industrial wet-type vacu-

um cleaner!

Mounting the water collecting ring

•

Loosen the fixation screw

14

on the water

collecting ring

15

.

•

Push the water collecting ring

15

onto the

drill stand and press it firmly against the

material to be drilled.

•

Tighten fixation screw

14

.

•

Connect a industrial wet-type vacuum

cleaner.

•

When using the water collecting ring,

attach a protective cover

13

onto it and drill

through. Remove te drilled part of the cover

from the core bit.

TRANSPORT AND STORAGE

CAUTION: Danger of injury and

damage! Pay attention to the

weight of the appliance when

transporting it.

•

Clean the machine and remove the drilling

dirt.

•

Transport the machine and core bit sepa-

rately.

•

Blow out remaining water from hose and

machine when it freezes.

•

This appliance may only be stored inside a

building.