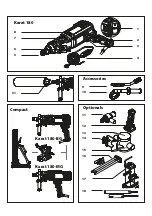

KARAT

®

180

US

12

OPERATING MANUAL KARAT® 180

REPLACEMENT PARTS

If – in spite of meticulous manufacturing and test-

ing processes – the device breaks down, have it

serviced by a B+BTec Service.

GUARANTEE

For this B+BTec appliance we grant a warranty in

accordance with the statutory/country-specific

provisions as from date of purchase (by evidence

of invoice or delivery note). Damage that has

occurred will be corrected either by replacement

or by repair.

Damage caused by improper handling is

excluded from the warranty.

Claims can be recognized only if the appliance

is presented in a not-disassembled manner to a

B+BTec branch office, your B+BTec field service

employee or a customer service office for power

tools authorized by B+BTec.

ENVIRONMENTAL

PROTECTION

Do not dispose of the appliance with

domestic waste. Dispose of the appli-

ance only via an authorized waste

management company or your

municipal waste management organ-

isation. Adhere also to the applicable regulations.

In case of doubt refer to your waste management

organisation. Recycle all packaging material in an

environmentally friendly manner.

INFORMATION ON NOISE AND

VIBRATION

Typically the A-weighted noise levels of the prod-

ucts are:

Sound pressure

level

EN-ISO 11203

Sound power

level

EN-ISO 3744

Karat 180

84 .6 dB (A)

97 .6 dB (A)

The typical hand-arm vibration for the main

handle is below 2.4 m/s

2

, for the auxiliary handle

below 4.6 m/s

2

.

Wear ear protection!

DECLARATION OF

CONFORMITY

We hereby declare that the appliance complies

with the relevant basic safety and health require-

ments of the EU Directives, both in its basic

design and construction as well as in the version

put into circulation by us. This declaration shall

cease to be valid if the device is modified without

our prior approval.

Karat 180

: EN-IEC 62841-1, EN-IEC 62841-2-1, EN-

IEC 62841-3-6

Conforms to the following standards or normative

documents 2006/42/EG, 2014/30/EU.

Zevenbergen, November 2019

R.G.W. van den Boogaart

General manager

B+BTec

Munterij 8

NL - 4762 AH Zevenbergen

+31 (0)168 331 260