7

abnormal noise or vibration occurs, have the problem corrected before further use.

Do not

use damaged equipment.

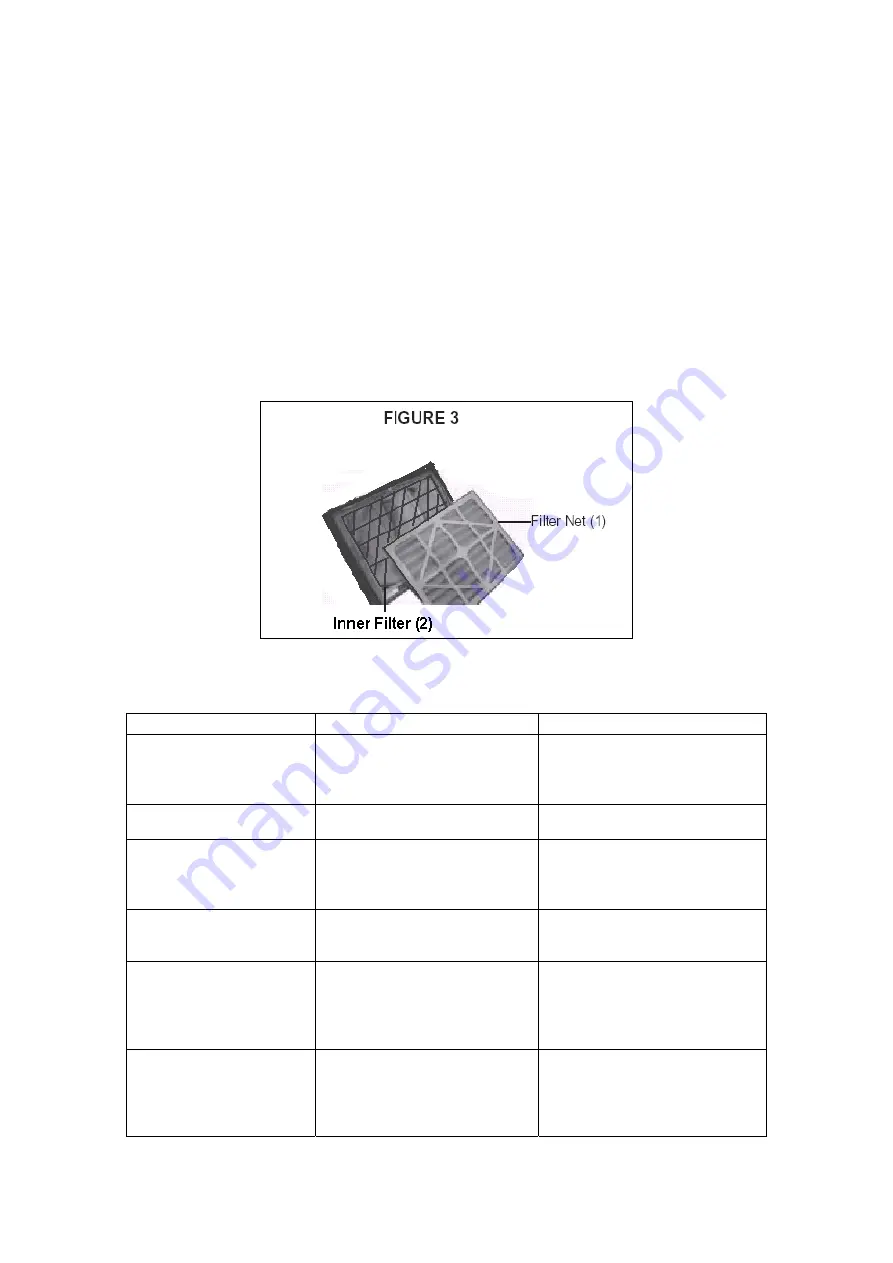

3. Periodically, inspect the Filter Net (1) for dirt and debris, and if necessary, remove and

change the Filter Net (1). On the rear of the unit, unlatch the two metal clasps to release the

Filter Net (1). Remove the Filter Net (1) and inspect it to see whether it needs a simple

cleaning, or it needs replacement. Reinsert a Filter Net (1) (old or new) and lock it in place

with the two clasps. (See

FIGURE 3)

.

Note:

During this procedure, wear ANSI approved safety goggles and dust protection.

4. Periodically, inspect the Inner Filter (2) for dirt and debris, and if necessary, remove and

change the Inner Filter (2). On the rear of the unit, unlatch the two metal clasps to release

the Filter Net (1). Remove the Filter Net (1). Then, remove the Inner Filter (2) and inspect it.

If necessary, use compressed air to blow dirt and debris from the Inner Filter (2) Replace

the Inner Filter (2) and the Filter Net (1) in the rear of the unit and lock them in place with

the two clasps. (See

FIGURE 3)

.

Troubleshooting

Note

: Any repairs suggested below should be completed by an authorized service technician.

Trouble Probable

Cause Correction

Motor does not run when

power switch is pressed

on.

1. Blown fuse.

2. Switch is burned out.

3. Connection wire is loose or

damaged.

1. Replace fuse.

2. Replace the Switch.

3. Tighten or replace the wire.

Motor does not run at full

speed.

1. Power voltage is too low.

2. Motor is damaged.

1. Test voltage.

2. Check and repair motor.

Motor will not reach full

power.

1. Incorrect power wiring.

2. Overload.

1. Replace incorrect power

wiring.

2. Reduce load by cleaning

filters as necessary.

Motor overheats.

1. Using wrong voltage.

2. Motor is damaged.

1. Check voltage and voltage

label.

2. Check and repair the Motor.

Insufficient suction power.

1. Inlet port blocked.

2. Filter Bag is full.

3. Outlet port blocked.

1. Clean inlet port.

2. Empty Filter Bag.

3. Clean the outlet port or

adjust the direction of the

outlet.

Unit is shaking.

1. The unit isn’t properly

anchored.

2. The unit isn’t level.

3. Worn or damaged power

cord.

1. Mount the unit firmly.

2. Level the unit.

3. Repair or replace power

cord.