Version 2.0.3 Preliminary Documentation – May be Subject to Change 35-36

General Specifications

Microprocessor

DSP56F8346

Control Logic

Standard embedded software is provided.

Quiescent Current Draw

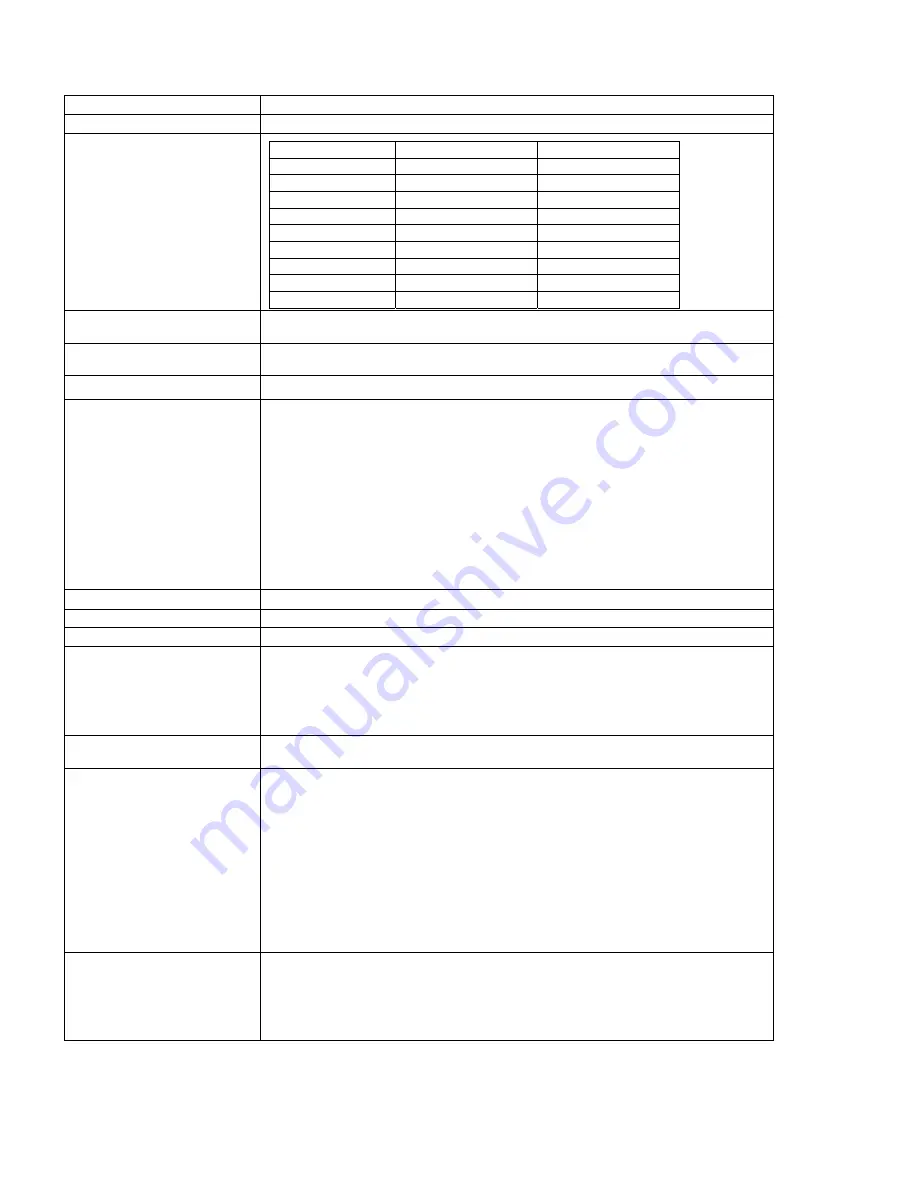

BATT+ Voltage (V)

Quiescent Current (ma)

Power - Watts (W)

9 269.8

2.43

10 241.8 2.42

11 220.3 2.42

12 200.5 2.41

15 159.3 2.39

20 115.1 2.30

24 95.9 2.30

28 82.4 2.31

32 72.4 2.32

Communications

1 CAN port (SAE J1939)

1 RS-232

User Interface

Electronic Assistant® for

Windows

operating systems

It comes with a royalty-free license for use.

CAN Interface

1 CAN port (SAE J1939)

Diagnostics

Each input channel can be configured to send diagnostic messages to the network if the

input goes out of range, as described below. In addition to the input channels, three other

types of faults can be reported to the network using diagnostic messaging. They are Over

Temperature (of the controller processor), Over Voltage and Under Voltage (of the power

supply voltage). For each fault condition, there are two setpoints, one that will cause the fault

condition to trigger, and the other that will clear the fault. Even if diagnostic messaging is not

enabled, the Minimum and Maximum Error setpoints can be used to flag an error using the

Axiomatic Proprietary B scheme.

Note: If the Input Sensor Type setpoint is set to either 16-bit Counter or Digital, diagnostics

are not permitted for that channel. Otherwise, whether or not faults will be detected for an

input channel is dependent on the settings of the “Minimum Error” and “Maximum Error”

setpoints.

If these are set to the limits of the range (i.e. 0V or 5V), then fault detection is not

possible.

Operating Conditions

-40 to 85

°

C (-40 to 185

°

F)

Protection

IP65, Unit is conformal coated in the housing.

Weight

2.30 lbs. (1.04 kg)

Electrical Connections

8-pin Deutsch IPD P/N: DT13-08PA

Mating plug p/n: DT06-08SA with wedge W8S and sockets 0462-201-16141

40-pin Deutsch IPD p/n: DRC13-40PA

Mating plug p/n: DRC16-40SA or DRC18-40SA with sockets 0462-201-16141

For pinout, refer to Section 1.6.

Packaging and Dimensions

Aluminum extrusion with stainless steel end plates.

For dimensions, refer to Section 1.6.

Grounding

Protective Earth (PE) must be connected to the grounding stud to reduce the risk of electric

shock. The conductor providing the connection should have a ring lug and wire larger than

or equal to 4 mm

2

(12 AWG). The ring lug should be placed between the nut and a star

washer. (To secure the ground strap, use an 8-32 “K-LOK” locknut, stainless steel, 3/8”

O.D.)

All chassis grounding should go to a single ground point designated for the machine and all

related equipment.

The ground strap that provides a low impedance path for EMI should be a ½ inch wide, flat,

hollow braid, no more than 12 inches long with a suitable sized ring lug for the module’s

grounding lug. It may be used in place of the PE grounding conductor and would then

perform both PE and EMI grounding functions.

Shielding

The CAN wiring should be shielded using a twisted conductor pair. All wire shields should

be terminated externally to the grounding lug on the mounting foot. The input wires should

not be exposed for more than 2 inches (50 mm) without shielding. Shields can be ac

grounded at one end and hard grounded at the opposite end to improve shielding. If the

module is installed in a cabinet, shielded wiring can be terminated at the cabinet (earth

ground), at the entry to the cabinet or at the module.