AV6A 14

Profinet IO “N”

Profinet IO is typically a master/slave network-the master/scanner

device gathers data from each (slave) device on the bus. Avtron

encoders are Profinet IO slave devices. Profinet IO commands

include a subset of Profidrive commands-these commands are also

supported by Avtron encoders. Avtron encoders support RT (real

time) and IRT (isochronous real time) functions.

Profinet IO may be wired in several different configurations, but

the best known is a “star” configuration where each device has a

“home-run” network cable that connects to a central switch or hub.

To reduce the cabling requirements, Avtron encoders support

“daisy-chain” configurations. The master device must be at one end

of the bus or connected to a hub or switch. The input signal from

the master or switch is repeated by each encoder to its output port

(labelled “Port 2”), which can in turn be connected to an input Port

1 of another encoder. No external or switched termination resistors

are required for Profinet IO. Power is carried to the device via a

separate set of wires. A maximum of (7) encoders can be daisy-

chained together to a single EtherNet/IP master/scanner or switch

port.

Preferred cable: Nidec Avtron recommends structured Ethernet

wiring systems, available from a broad range of vendors as well as

Avtron.

For more details on Profinet, consult the Profibus Users Association

(PI):

http://www.profibus.com/

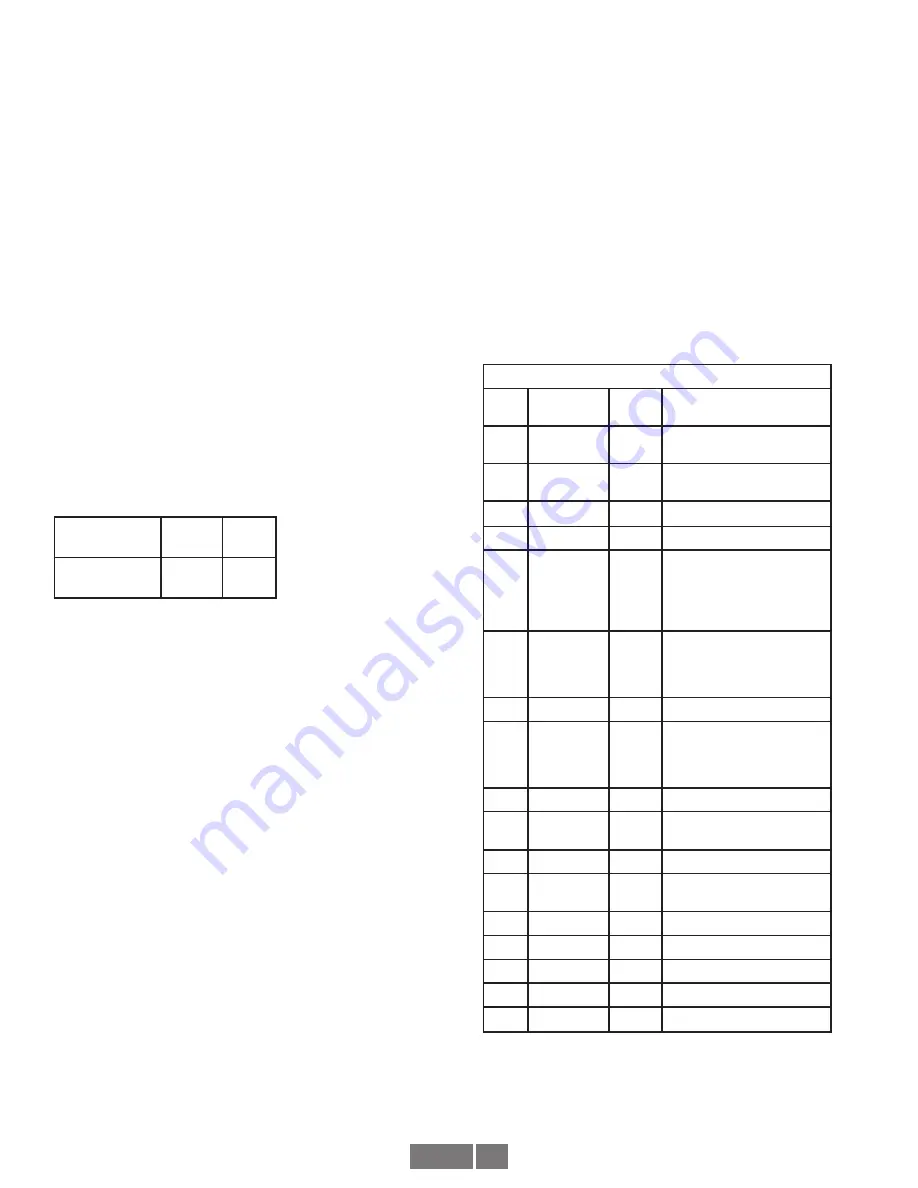

Number of

Nodes

1-7

Units

Max. Overall

Cable Length*

330

[100]

ft

[m]

*Using Ethernet standard cable, CAT6 or CAT5e required

Setting Station/Node, Baud Rate, Duplex

NOTE: There is no hardware method to set the Station/Node number

(IP address) for Avtron EtherNet/IP address.

Setting IP Address via STEP7 (Siemens) software:

Begin with a factory-default encoder. Make a physical Ethernet

connection between a PC and the encoder. Run the STEP7

software. Under menu item PLC->Ethernet->Edit Ethernet Mode-

>Browse. STEP7 will produce a list of all encoders via MAC-

address. Optional: use the flash LED button to cause the LED

to flash to verify communication with the encoder. Select menu

item Use IP Parameters, enter the IP address then->Assign IP

Configuration. Enter the device name. Any IP address from 0.0.0.0

to 223.255.255.255 (excluding 127.x.x.x) is permitted.

Cycle power.

The encoder should now operate at the assigned IP address,

which can be validated using the ping command from the PC. The

assigned name can be used throughout STEP7 software to address

the encoder.

Note that if more than one encoder is to be used on the same

Profinet IO network, each encoder must be assigned a unique name,

and individual encoders must be connected one-by-one to assign

names using STEP7 software during setup.

Ethernet baud rate and duplex are auto-detected by the encoder, no

settings are required. 100mBit and 10mBit are supported, Gigabit

Ethernet is not supported at the encoder level but may be utilized at

the switch backbone level. Consult Nidec Avtron if manual forcing of

duplex is required.

Measuring Position, Speed, and Acceleration

Avtron encoders support three modes of operation:

Standard

Profile (Profidrive) 4.0 (supports DP-V2 commands)

Profile (Profidrive) 4.1 (supports DP-V2 commands)

Profile 4.0 and 4.1 require a special GSDML file, contact factory.

To read position and speed into your device (acceleration

measurement is not supported directly):

Following the instructions for your master/scanner module for

the Profinet IO network, load the encoder GSDML file into your

configuration. Assign it to the correct IP address node number.

Store the configuration to the scanner module.

All of the position data and other parameters will be read by

the scanner module and placed in registers identified in the

configuration package.

Cyclic Data

ID

(dec)

Function

Type

Notes

3

Master

heartbeat

UINT

4

Slave

heartbeat

UINT

6

Velocity

INT

8

Velocity

DINT

9

Ctl Word

UINT

bit 11=preset/zero

bit 12=capture position

bit 13=enable cyclic xmit

bit 14=disable error xmit

bit 15=clear errors

10

Status

UINT

Bit 12=ack capture position

Bit 13=ack cyclic xmit req

Bit 14=ack disable error

Bit 15=encoder error

11

Position 1*

DINT

12

Position 2*

DINT

If encoder error (bit 15,

ID10), error message output

to Position 2 instead of

position.

39

Position 3

DINTx2 right-aligned

19

Vel. Update

EUINT

0=1sec, 1=0.1s, 2=0.01s,

3=RPM

29

Status

BYTE

2A

Units per

span

UDINT

read only, set w/0x10

2B

# Spans

UINT

# revolutions

33

Offset

DINT

Poffset

64

Device Type DINT

0x22 = Encoder

65

Rollover

DINT

0=off, 1=on, 2=auto

66

Vel’cty Filter DINT

0=low pass, 1=mid, 2=off

* Depending on the mode of operation selected, the position data is

aligned differently, but always presented little-Endian (right most bit

is least significant):

Standard Profile: data is right-justified: Single-turn data/data within