05/08 Rev. AB

OPERATOR’S HANDBOOK

Getting Started

9844/9854

1-6

9854 with

Dispenser

(Peel) and Liner

Takeup

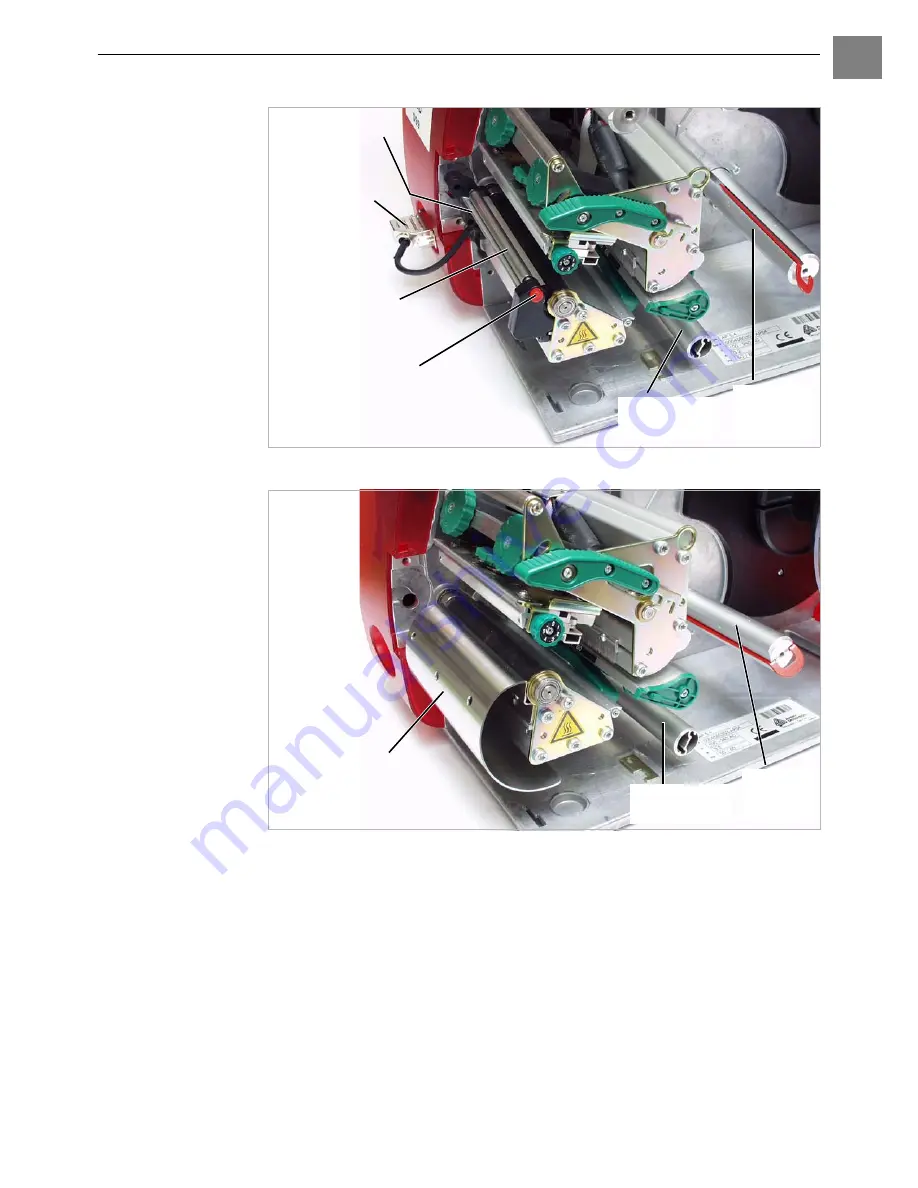

Fig. 6:

Additional operating parts of the printer with dispenser.

Fig. 7:

Additional operating parts of the printer with internal liner takeup.

Dispensing edge

Removes the labels

from the backing

paper.

Dispensing roller

Holds the material

tight over the

dispensing edge.

Dispensing roller release button

Press the button to release the

dispensing roller.

Connector

Connection of the

dispensing edge

sensor.

Takeup Reel

Wraps up the

backing paper.

Deflector

Deflects the

backing paper.

Takeup Reel

Wraps up the

labels.

Deflector

Deflects the labels.

Deflector

Deflects the printed label

without dispensing any

labels.