2

Once inspection is performed, the evaluation board can be used to test either one of the top and bottom half bridge

inverter arms in simulation mode without the need for a IGBT or SiC/GaN MOSFET. To perform testing simply follow the

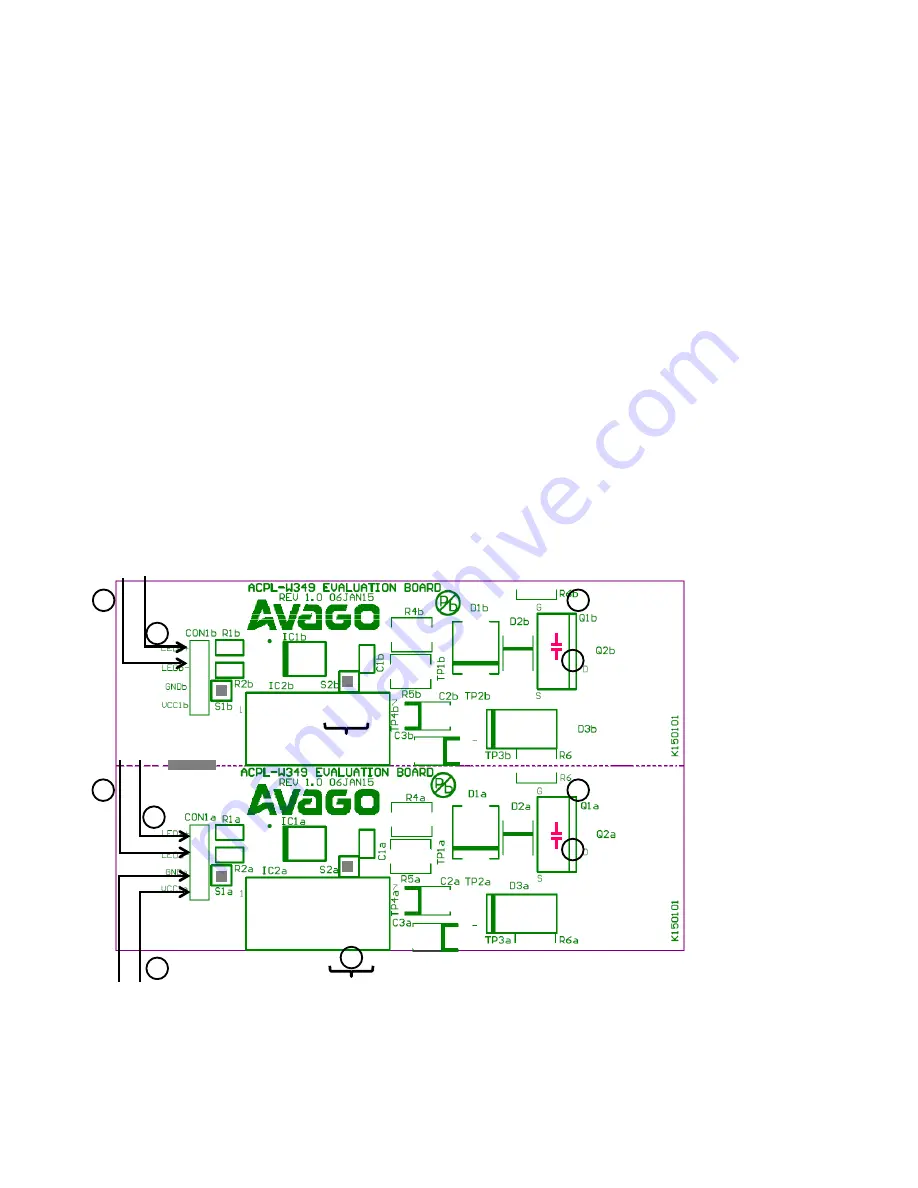

five steps as outlined below (See Figure 2).

Testing both Arms of The Half Bridge Inverter Driver (without IGBT or SiC/GaN MOSFET)

1. Solder a 10nF capacitor across Gate and Emitter/Collector terminals of Q1 or Q2 (to simulate actual gate capacitance

of IGBT or SiC/GaN MOSFET)

2. Connect a +5V DC supply (DC supply 1) 5V and GND terminals of CON1

3. Connect another DC supply (DC supply 2 with voltage range from 15V~30V) across Vcc2 (pin-7 of IC2) and Vee (pin-5

of IC2) terminals of IC2a respectively. This can be non-isolated for testing purposes

4. Connect drive signals;

a) A 10kHz 5V DC pulse (at slightly <50% duty) from a dual output signal generator across IN1+ & IN1- pins of CON1a

to simulate microcontroller output to drive lower arm of the half bridge Inverter

b) Another 10kHz 5V DC pulse (at 180

°

out of phase to 4a) from the dual output signal generator across IN2+ & IN2-

pins of CON1b to simulate microcontroller output to drive upper arm of the half bridge Inverter

5. Use a multi-channel digital oscilloscope to capture the waveforms at the following points;

a. LED signal at IN1+ pin with reference to GND

b. LED signal at IN2+ pin with reference to GND

Note: Vcc2b supply of voltage close to Vcc2a should then be successfully generated through the built-in bootstrap components D3b and R6.

c. Vga representing the output voltage of ACPL-P349/W349 (IC1a) at Gate pin of Q1a (or Q2a) with reference to Vea

d. Vgb (through an isolated probe) representing the output voltage of ACPL-P349/W349 (IC1b) at Gate pin of Q1b (or

Q2b) with reference to Veb

Figure 2. Simulation Test Setup of Evaluation Board

10nF

In1+

In1

-

Signal Input

+5V

Gnd

DC Supply1

15~30V

+

-

10nF

Vcc2b

+

-

In2+

In2

-

Signal Input

5a

5c

5d

Vea

Veb

DC Supply2

1

2

4a

3

1

4b

5b