15

UK

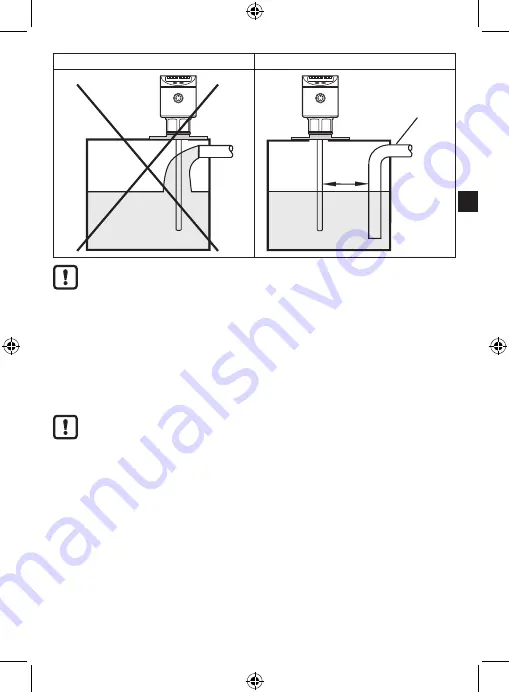

Fig. 6-3

Fig. 6-4

50mm

A

To avoid incorrect measurements in case of heavy foam formation and

turbulence:

► if possible, install the sensor in a steady area�

Example how to create a steady area:

-Use of a coaxial probe (only for clean, low-viscosity media)

-Installation in bypass or still pipe (see fig� 6-5)

-Separation of the installation location by metal sheets / perforated sheets

(without figure)

Minimum diameter of the bypass and still pipe: d = 100 mm�

The upper access to the steady area (fig� 6-5: A / B) has to be above

the maximum level� The lower access (fig� 6-5: C / D) or the area with

perforated sheet etc� has to be below the minimum level� This ensures

that neither foam nor turbulence impact the sensor zone� When perforated

sheets or the like are used, soiling (e�g� by metal swarf, particles, ���) can

also be avoided�