Page 9 of 26

7/9/19

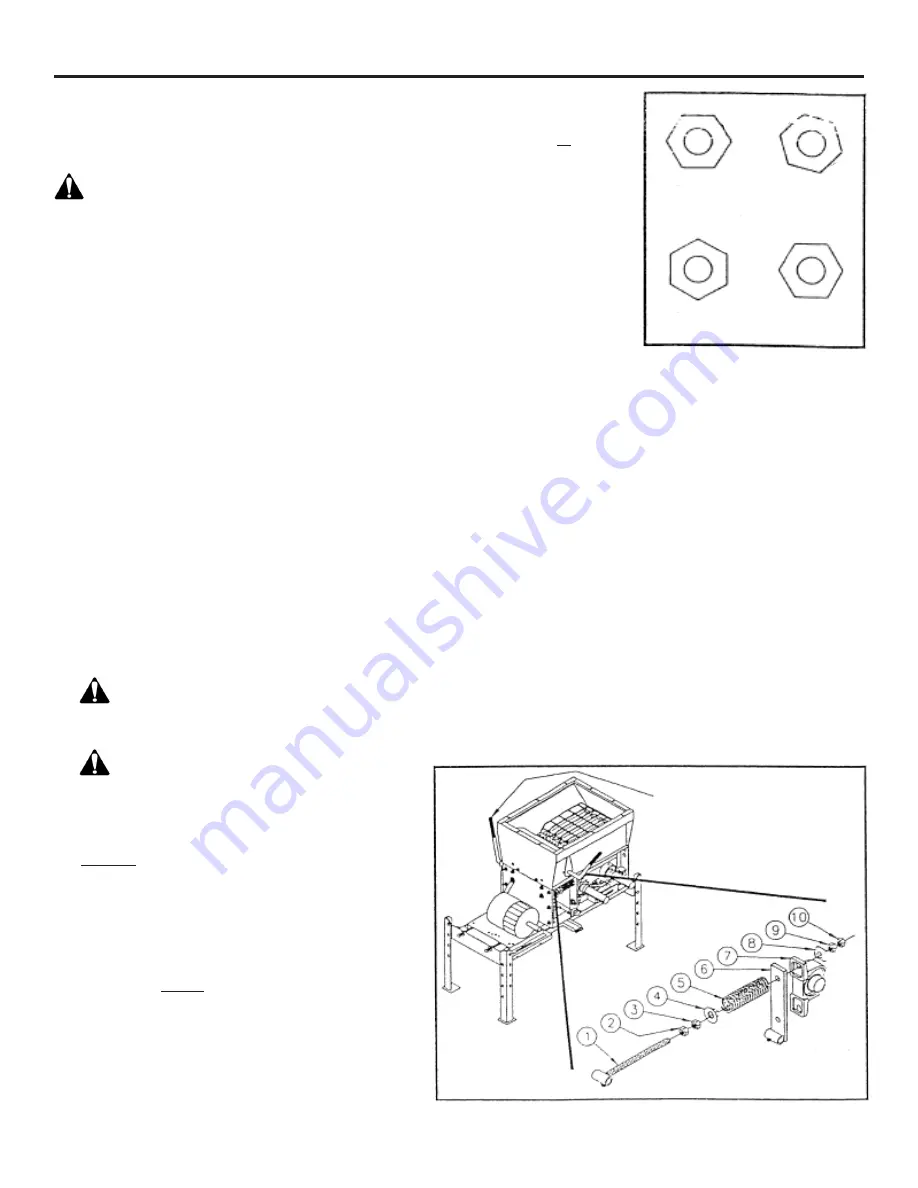

6 Once the roll teeth

touch, turn the

nuts (9) IN about

1/4 to 1/2 flat on

the nut. (See

Figure 7).

NOTE: There are

six flat sides on

each nut. Turning

one full flat means

turning the nut so

that the flats

advance one

position.

7 Hold the nuts (9) in

place and tighten the jam nuts (10) on both sides of

the mill. Recheck that the rolls do not touch by

repeating step 5.

8 Move the roll spacing adjustment handle 50 each way

from center and check to assure the rolls are not

touching. Readjust if necessary. Be sure to tighten jam

nuts (10) when finished.

9 If adjustments were made, measure the length of the

springs (5). They should be 4 1/2” long ±1/8”. If

spring adjustment is needed, loosen the jam nut

(2) on the spring side and move spring nut (3) until

the correct spring length is established. Once

adjusted, tighten the jam nut (2) to hold setting.

10 Make a final check of the rolls for parallel and roll

gap. You may need to use a feeler gauge for 8 cut and

finer rolls. Reinstall the drive belt and shields. Be sure

to remove any tools from the machine before

restarting.

Figure 7

Figure 8

REALIGNING ROLLS

REALIGNING ROLLS - If the rolls ever become out of

alignment (more gap on one end of the roll pair than

the other) they must be realigned to maintain feed

consistency and prolong the life of the rolls. To accomplish

this, follow the instructions below.

DANGER: Before attempting to service your

roller mill be sure to follow the SAFETY SHUTDOWN

PROCEDURE on page 2.

1

Remove the drive belt from all the pulleys and lay it

aside. Loosen the jam nut (item 10) on one of the

sides of the mill. It may be necessary to loosen and

adjust both sides to acquire the correct settings. This

will be determined by how far out of parallel the rolls

are.

2 Adjust the other nut (9) on the same side, until the

rolls are parallel. To check for roll spacing, a strip

of metal banding works well but any strip of metal

approximately 1/32” thick will also work. Slide the

strip between the rolls and verify the roll spacing is

the same along their entire length. Check the spacing

3 or 4 times with the rolls at various rotated positions

to assure the rolls are as close to parallel as possible.

NOTE: Rolls will vary a few thousandths of an inch

in diameter along their length, be sure to check for

the tightest gap.

3 With the rolls parallel you can now set the roll

spacing. Place the roll spacing adjustment handle

straight up with the indicator straight down. This will

place the rolls at their closest possible setting.

4

WARNING: Be careful not to get your hands

between the rolls or between the rolls and the basic

channel.

WARNING: Do not power the mill with the

motor. This creates a personal danger to you and

may cause damage to the rolls if they are touching.

5 By hand, spin the rolls in the same direction

(clockwise) at different speeds. Strike the idler roll

shaft at the bearing, towards the drive roll, with a

rubber mallet to ensure that the idler bearing

mount (6) is free to allow the rolls to be at their

closest position. With the rolls spinning freely at

different speeds, turn the nuts (9) on both sides of

the mill out evenly until you hear the roll teeth

touch. They will make a ticking sound that should

be easily heard. This is to ensure that the rolls do

not move closer together with the vibration of the

mill. Some additional adjustment may be needed

at this time.

292-1329 5/94

ROLL SPACING

ADJUSTMENT

ORIGINAL

1/2 FLAT

1/4 FLAT

1 FLAT

1

1

1

1

2

2

2

2

3

3

3

3

4

4

4

4

5

5

5

5

6

6

6

6