© 2012 G Force Automatic Gates All Rights Reserved

Warranty & Returns

POLICY

GENERAL

Automatic Gate products are

covered by the manufacturer’s warranty which covers defects in materials and workmanship for the

Warranty Periods stated below. This warranty is additional to any applicable statutory requirements, subject to the exclusion s and

limitations stated below.

Product is deemed to be warranted from the date of initial purchase from G-Force Automatic Gates. Proof of purchase is required when

applying for warranty claims.

Warranty is offered on a Back-to-

Base Warranty basis. Where issues can’t be resolved by your Installer or local Reseller in person, or by

Staff over the phone, product will need to be returned at Customer Cost to for assessment, repair or replacement.

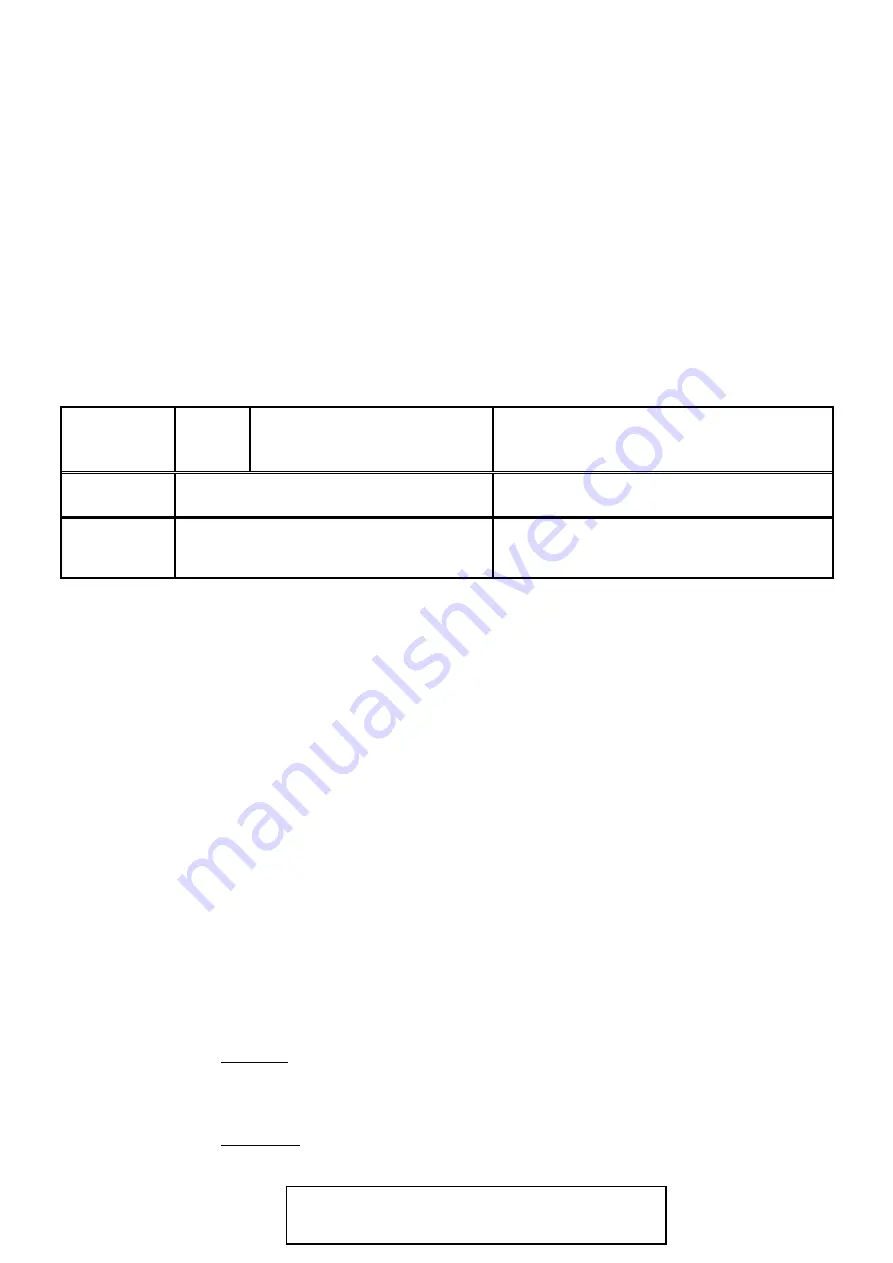

1

year

DIY

Gate Kits

Applicable Kits:

FG 5, SW 5, DSW 5, SL2000,

1

year

Visitor Access & Hardware

Such as:

Intercoms, Keypads, PE Beams, Loop Detectors, etc.

3

month

Spare Parts

(exclusive of warranty replacements)

Such as:

Control Boards, Receivers, Remote Controls, Gears,

Limit Switches, Brushes, etc.

Warranty Periods

Exclusions & Limitations

The warranties stated herein do not cover damage, malfunction or service failures caused by:

Failure to follow G-Force or Product Installation, Operation or Maintenance Instructions

Repair or modifications to your G-Force product by someone other than a G-Force Service Technician, Authorised Installer or

Reseller

Abuse, misuse or negligent acts

Batteries or Fuses supplied with your G-Force product (inc Handset batteries)

Power failure surges, lightning, fire, water damage, pest damage, accidental breakage, actions of third parties and other events

or accidents outside of G-

Force Automatic Gate’s reasonable control and not arising from normal operating conditions

G-Force Automatic Gates is not responsible for any special, incidental, consequential or punitive damages arising from the use

or

1

Request

To lodge a claim, contact G-Force Automatic Gates on 1800 111 930 for assignment of an

RMA No.

(Returns Material Authorisation No.). This number should be recorded on each box of returned goods to

enable in-house tracking of your goods

2

Return Goods

to G-Force

Goods are to be returned to G-

Force Automatic Gates at the Customer’s cost. G-Force will assess returned

product within 7 days to determine the extent of warranty cover and likely repair costs

3

Repair or Re-

placement of

Goods

In-Warranty

Repairs will proceed as soon as practicable. The manufacturer’s offering the warranty

reserves the right to repair or replace product at its discretion. It may, at its discretion, use new, remanufac-

tured, or refurbished parts or products when repairing or replacing product. Replaced parts become the

property of G-Force Automatic Gates. Repair costs and return freight of in-warranty repairs will be covered

free of charge

Non-Warranty

Repairs will not proceed until you are notified of estimated Repair Costs, we receive authori-

sation and payment details from you to proceed. Where product is deemed to be unrepairable, and you re-