- 61 -

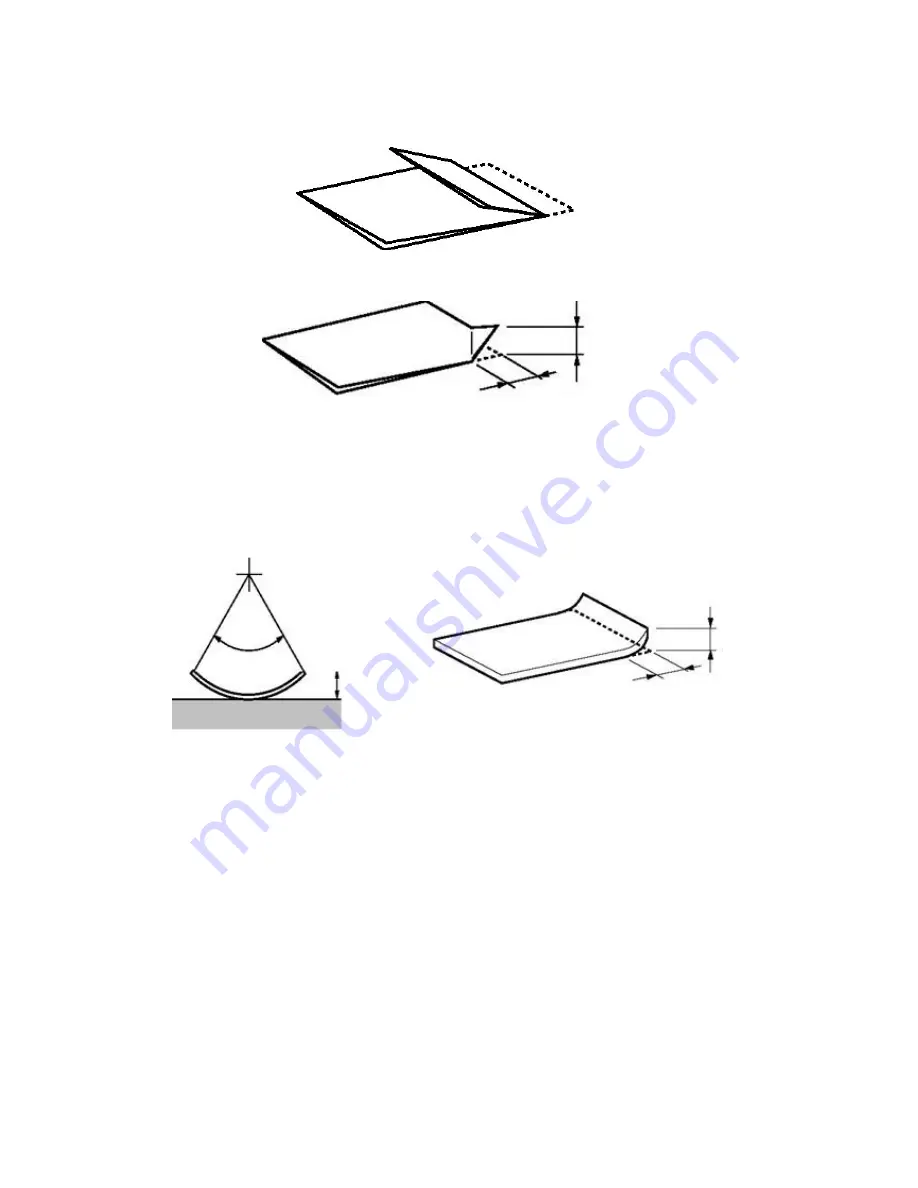

• Paper with the whole page folded can not be used.

(As the paper strength has been changed even after amending.)

• Please amend the fold of the corner to less than 2 mm.

○

Bend and curliness (cut sheet, tractor paper)

• The paper can be used when the bend of the whole page is less than 2 mm.

• The bend length starts from the bend point should within 15mm. But when the bend height is

over 2 mm, paper can not be used.

8.1.4 Tractor Paper

Tractor paper is the continuous paper which has gear holes and the traverse perforations lines.

Refer to the following table for the requirement of tractor paper.

Paper with the whole page folded can not be used.

The fold of corner

Amend it to

less than 2mm

More than 15 mm

Bend

Amend it

to less

than 2 mm

Less than 15 mm

Whole page bend

Less than 2 mm

Arc