128-7410

7 of 20

Page 7

THE TRANSCEIVER/ANTENNA ASSEMBLY:

The Superheterodyne Transceiver Antenna Assembly provided with this unit allows routing from below the dash-

board for maximum operating range. Choose a location above the belt line (dashboard) of the vehicle for best

reception. Special considerations must be made for windshield glass as some newer vehicles utilize a metallic

shielded window glass that will inhibit or restrict RF reception. In these vehicles, route the antenna toward a rear

window location for best reception. Secure the antenna with double stick tape provided. After securing the antenna

with tape, we advise also securing a section of the antenna cable to a fixed support. This will prevent the antenna

from dropping down in case the double stick tape is exposed to extreme heat, which may loosen its gummed

surface. Route the 4 pin connector toward the control module using caution not to pinch the cable as this will cause

poor or no RF reception to the control module.

I M P O R T A N T !

DO NOT PLUG THE SIX PIN MAIN POWER HARNESS OR THE MULTI PIN INPUT / OUTPUT HARNESS INTO THE

CONTROL MODULE UNTIL ALL CONNECTIONS TO THE VEHICLE HAVE BEEN MADE. AFTER SELECTING YOUR

TARGET WIRES AS DEFINED BELOW, DISCONNECT THE NEGATIVE BATTERY CABLE FROM THE VEHICLE BAT-

TERY PRIOR TO MAKING ANY CONNECTIONS.

WIRING THE 6 PIN MAIN POWER HARNESS:

RED w/ WHITE TRACE WIRE:

+ 12 volt Battery 1 Source

Connect this wire to a + 12 VDC constant source found at the vehicle's ignition switch using the 30 Amp fuse and holder

provided. This wire provides power for the control circuit as well as the ignition 1 and ignition 2 relays.

RED WIRE:

+ 12 Volt Battery 2 Source

Connect this wire to a separate,

(Other than the wire Red or Red/Black is connected to),

+ 12 VDC constant

source found at the vehicle's ignition switch using the 30 Amp fuse and holder provided, but NOT the same vehicle

wire as used by the battery 1 source. Most vehicles have more than one battery source supplying power to the ignition

switch. Separate feed wires must be used for the Red and Red/White wires. If your vehicle does not have two battery

feed wires at the ignition switch then it is possible to connect both wires to the vehicle's battery. This wire provides

power for the start relay and the accessory relay.

I M P O R T A N T !

IT IS THE RESPONSIBILITY OF THE INSTALLING TECHNICIAN TO DETERMINE THE LOAD FACTOR OF THE

VEHICLES ELECTRICAL CIRCUITS WHEN THE VEHICLE IS RUNNING AND TO ADEQUATELY FUSE THE TWO

POWER WIRES BASED ON THAT LOAD. IF THE VEHICLE, RUNNING UNDER LOAD WITH THE AIR CONDITIONER,

HEATER BLOWER MOTOR, AND ACCESSORIES EXCEEDS 24 AMPS CONTINUOUS, WE RECOMMEND THAT

TWO FUSES BE USED IN COMBINATION ON EACH POWER WIRE AS SHOWN BELOW. FOR ADDITIONAL INFORMA-

TION SEE TECH UPDATE ISSUED 9/30/96.

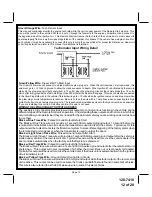

YELLOW WIRE:

Starter Output

Careful consideration for the connection of this wire must be made to prevent the vehicle from starting while in

gear. Understanding the difference between a mechanical and an electrical Neutral Start Switch will allow you

to properly identify the circuit and select the correct installation method. In addition you will realize why the

connection of the safety wire is required for all mechanical switch configurations.

Failure to make this connection properly can result in personal injury and property damage. In all installations it is the

responsibility of the installing technician to test the remote start unit and assure that the vehicle cannot start via RF

control in any gear selection other than park or neutral.

In both mechanical and electrical neutral start switch configurations, the connection of the Yellow wire will be made

to the low current start solenoid wire of the ignition switch harness. This wire will have +12 volts when the ignition

switch is turned to the start (crank) position only. This wire will have 0 volts in all other ignition switch positions.

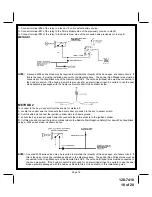

NOTE:

This wire must be connected to the vehicle side of the starter cut relay (when used). For the electrical neutral

switch configuration, this connection must be made between the starter inhibit relay, (when used) and the

neutral safety switch as shown in the following diagram.