REV. 01 2014

15 / 41

Continue until the first bead is fully detached. To

facilitate this operation, lubricate the bead and the

edge of the rim with tire lubricant whilst the wheel is

rotated.

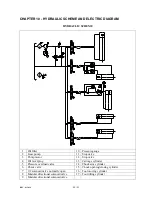

Bring the tool-holder arm (10/fig. A) away from the rim. Raise the tool holder arm to its non-

working position, shift it and re-hook it in its second work position.

Repeat the operation previously described until the second bead is completely detached.

Go on pushing the tire until the rim comes completely out.

5.6 MOUNTING TUBELESS TIRES

Make sure that the rim is locked on the self-centering chuck.

Lubricate the beads and rim carefully to facilitate the mounting

operations.

Fix the pliers at the outer rim edges at its highest point. Make

sure the clip is firmly attached to the rim.

Lower the chuck to allow locking the first bead with the pliers

(make sure it at the high point).

Lift the rim with the tire fixed and turn it anticlockwise about

15-20 cm. The tire will be positioned tilted across the rim.

Lower the tool-holder arm into is working position.

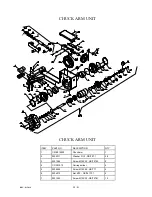

Operate the joystick 1 to position the roller against the second

tire bead and turn the tire until the pliers is at the lowest

position. The first bead should be set on the rim at this time.

Position the roller at a distance of 4-5mm from the rim and

press on the second tire bead in order to fit the pliers (E/11).

Turn clockwise and lubricate the beads and the rim with the

proper grease. At the same time, advance the roller with small

movements towards to the rim center until the tire is completely

set on the rim as shown in the figure E/12.

Remove the pliers out of the rim and bring the tool-holder arm

out of the working position.

Lower the chuck, and then close the chuck jaw to set the wheel

on the frame plate vertically.

To avoid all risks, rotate the wheel

clockwise when operating on the outside

plane and anticlockwise when operating

on the inside plane.

Do not keep your hands on the tool when setting it in working position so as to

avoid any possible crushing between the tire and the tool.

A mechanical lifting device must be used when handling wheels weighing more than

240 lbs.

Tire inflation must be done by placing the tire inside the safety cage.

Summary of Contents for TTC305

Page 1: ...REV 01 2014 1 41 ...