REV. 01 2014

5 / 41

CHAPTER 2 – GENERAL INFORMATION

2.1 I

NTENDED USE

This

tire changer has been designed and manufactured exclusively to be put on a can for

removing and mounting truck, bus and commercial van tires from/onto rim bores from 8" to

23" and a tire at maximum diameter of 55".

In

particular the manufacturer

cannot be held responsible for any damage caused through the

use of this tire changer for purposes other than those specified in this manual, and therefore

inappropriate, incorrect and unreasonable.

2.2 GENERAL

SAFETY PRECAUTIONS

The machine should only be used by duly authorized and trained personnel.

The machine should not be used for purposes other than those described in the instruction

manual.

Under no way should the machine be modified except for those modifications made explicitly

by the manufacturer.

Never remove the safety devices. Any work on the machine should only be carried out by

specialist personnel.

Any tampering or modification to the equipment carried out without the manufacturer’s prior

authorization will free him from all responsibility for damage caused directly or indirectly by

the above actions.

Removing or tampering with safety devices immediately invalidates the guarantee.

The tire changer comes complete with instruction and warning transfers which are designed

to be long-lasting. If they should for any reason be damaged or destroyed, please ask

immediately for replacements from the manufacturer.

The machine operator should avoid wearing clothes with flapping edges. Make sure that

unauthorized personnel do not approach the machine during the work cycle.

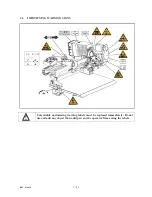

2.3 SAFETY DEVICES

The tire changer has a number of safety devices designed to

guarantee the upmost safety:

Check valve on the spindle opening hydraulic line

(inside the swivel connector, see fig. B/1). This

prevents the wheel from falling from the spindle if the

hydraulic line is accidentally broken.

Pressure relief valve set at 130 bar ± 10%

(see fig.

B/2). This limits the pressure in the hydraulic line and

ensures correct operation of the plant.

Pump motor overload cut-off

(inside the electric

enclosure). This cut prevents the motor from burning

out if it overheats.

Check valve on the chuck arm lifting hydraulic line

.

It prevents the chuck arm from descending when any

accidental break occurs in the hydraulic line. .

Summary of Contents for TTC305

Page 1: ...REV 01 2014 1 41 ...