Page 36 / 56

00BNO9132-#

VARMAX TWIN -

Installation, Use and Maintenance

For a request via 0...10V input

• Inputs/outputs test

menu

Voltage in H1

H1 voltage signal (7840)

To be validated with

the voltage sent by

the boiler room's

PLC

For a request via LPB

If the boiler room's regulator is confi gured

as slave clock, it must retrieve the date

and time.

• Inputs/outputs test

menu

Check the outputs

Alarm relay

Relay test (7700)

Relay output QX1

Isolating valve Q1.1

Relay test (7700)

Relay output QX3

Reset the outputs

Relay test (7700)

No test

Check the sensor values

External sensor B9

External T° B9 (7730)

in °C

B1 fl ow sensor

BX2 sensor T° (7821)

in °C

• Confi guration

menu

Check the hydraulic diagram

Generator 1 inspection No. (6212)

14

Generator 2 inspection No. (6213)

0

DHW information (6215)

0

Information about heating circuits 3, 2 and 1 (6217)

0

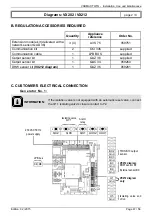

Diagram: VX211

page 5 / 6

E. ELECTRICAL AND HYDRAULIC VALIDATION

On generator No. 1

Line No.

Value

• Flow diagnostic

menu

Validate the presence of all the generators

Gener 1 status (8100)

Released / not

released

Gener 2 status (8101)

Released / not

released

...............................

Summary of Contents for Varmax Twin

Page 2: ......