Machine Maintenance

Drive Sprocket Rollers

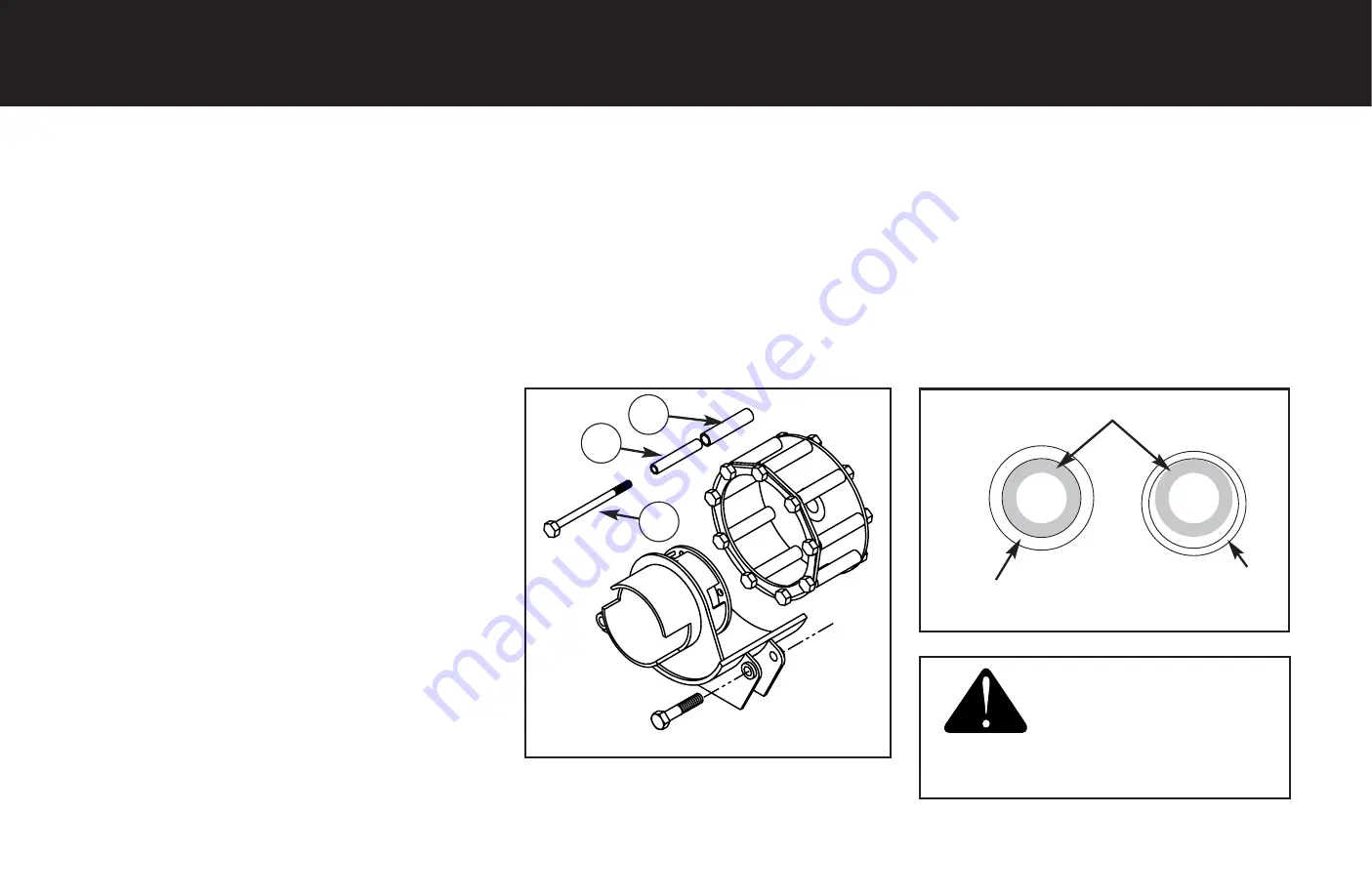

Rubber Track Loaders use rollers on

each drive tooth of the two drive sprock-

ets. These rollers help minimize friction

between lugs on the track and the

sprocket. Sprocket rollers should be

treated as wear items that are inspected

regularly and replaced as needed.

The rollers rotate on steel pins, limit-

ing wear to the inside of the rollers. As

they wear, the rollers become thinner,

but will continue to function and per-

form as long as they are rotating.

Visually inspect rollers every 50 hours

and replace any that show signs of

cracking or wear-through.

Rollers can be replaced without

removing the track. Simply remove the

bolt (1) holding the steel pin (2) and the

roller (3) in place. Install a new roller

over the steel pin and re-install the pin

and roller into the sprocket. Normally,

two rollers can be replaced before the

sprocket needs to be rotated.

21

!WARNING!

Make sure the machine is turned

off, the key removed and the

battery disconnected before performing this

procedure.

Steel Pin

New Roller

Normal Roller Wear

at 50% life

2

1

3