12

HEATING BOILERS

: Astra G-18 E, Astra G-25 E, Astra G-32 E, Astra G- 40 E

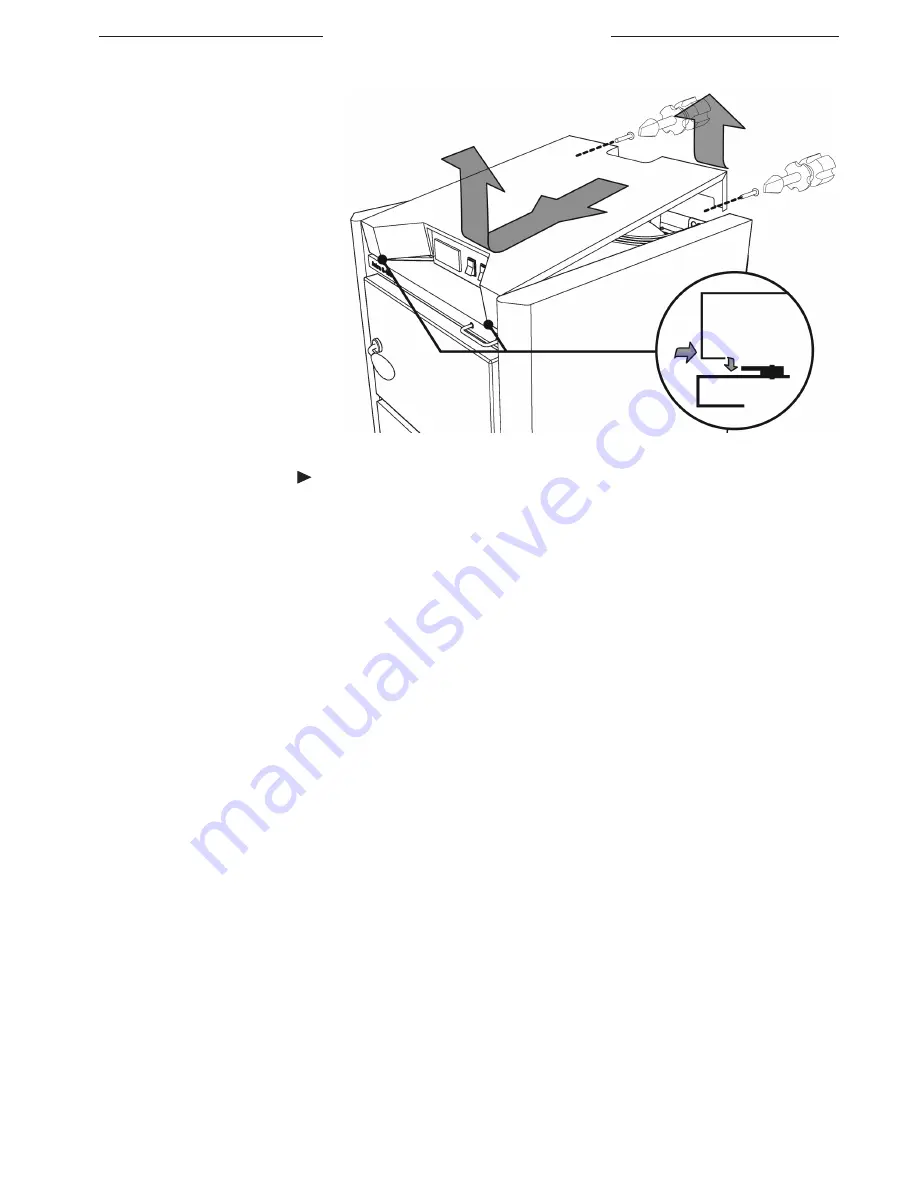

• connection of the

cIRcUlaTIon PUMP

In order to insure a continuous flow of

water, a circulation pump is to be installed

in the system, on the return water pipe

behind the mixing valve. The electronic

controller of the boiler controls the

pump. Before connecting the circulation

pump, remove the rooftop cover of the

boiler (Fig. 7). The cover is removed in

the following sequence: 1) unscrew two

fastening bolts, 2) lift the backside part

of the cover, 3) push the cover forward

and then lift it up. Connect the wire of

the circulation pump to the 12-way

electric terminal connector, contacts No

11 and 12, marked with the sign (See

Fig. 6 “Circuit diagram of the boiler”). Connect the earthing wire of the pump to the contact No. 1 on the same connector.

• connection of the Ventilator

The boiler is transported with the ventilator removed and put into the upper chamber of the boiler (Astra G-18E, Astra

G-25E, Astra G-32E) or fastened using adhesive tape to the top of the packaging frame of the boiler (Astra G-40E).

For boilers Astra G-18E, Astra G-25E, Astra G-32E: unpack the ventilator and release the clamp on the nipple at the ventilator

installation bed 10 (Fig. 1). Put the opening of the ventilator onto the nipple, slip a clamp on top and tighten it. Check if a ventilator

case sits tightly. Connect the wires of the ventilator cable lead through a hole in the rooftop cover of the boiler to the terminals of

the ventilator. For boilers Astra G-40E: unpack the ventilator, screw its case on at the ventilator installation bed 10 (Fig. 1) using

the existing bolts and check the stiffness of the connection. The ventilator cable has already been connected during fabrication.

• controllinG the temPerature of water returninG to the Boiler

It is absolutely necessary to maintain the temperature of the water returning from the heating system to the boiler at a

constant level, no less than 65°C, as this will prolong the lifetime of the boiler and will make the combustion process more

effective. This is because when a constant high temperature of water returning to the boiler is maintained, there arises

significantly less water vapour condensation inside the boiler. The heavy water condensation is harmful to the boiler, because

deposits of tar, pitch and soot accumulate on the walls of the heat exchanger, causing intense metal corrosion. Moreover, the

resulting layer of soot impedes effective heat transfer and the efficiency of the boiler falls.

In order to maintain the temperature, we recommend installing the small circulation circle together with a Swedish-made

thermoregulation device, “Laddomat 21-60”. Make sure that the “Laddomat” is supplied with the 78°C or 72°C thermostat

cartridge. The mentioned temperature is the one at which the valve of the device opens completely. However, the actual

temperature of the water returning from the system and getting into the boiler after mixing, is 5-6°C lower. The higher the

temperature of the return water is, the better it is for the boiler. Thermoregulation devices of other manufacturers could be

used for maintaining the temperature of the returning water as well.

• heatinG outPut, water temPerature anD water flow relationshiP

The heating output supplied to a heating system depends directly upon the difference of flow and return water temperatures

fig. 7 Removing the rooftop cover of the boiler

1. Unscrew bolts; 2. Lift the backside of the cover; 3. Push the cover forward , then raise.

3

1

1

2