:: Tuning Tips

Recommended Motor Gearing:

To calculate your SC10 4x4 Final Drive Ration (a.k.a. gear ratio), use the following formula:

(spur gear # teeth) / (pinion gear # teeth) x 2.57 = Final Drive Ratio

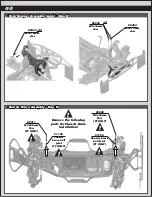

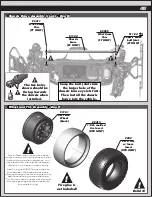

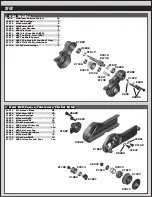

Differential:

The SC10 4wd heavy duty differentials (a.k.a. “diffs”) are o-ring sealed, and can be filled with silicone fluid.

The recommended starting setup is 30,000 CST front and 5.000 CST rear.

For less low-speed steering, try running the front differential thicker than the rear (example, 3000 CST rear, 5000

CST in front). The truck will have the best cornering balance with more similar fluids in the front and rear diffs.

Slipper Clutch:

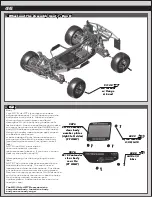

The assembly instructions give you a base setting for your slipper clutch. The SC10 4wd clutch is de-coupled, so the

outer slipper hub drives the rear wheels and the inner slipper hub drives the belt to the front. The Team recommend

making slipper settings at the track, where the grip level is at race conditions.

Torque bias front and rear is adjustable by changing the center hole diameter in the slipper pads.

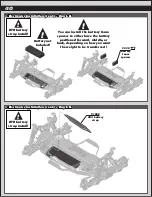

Belt Tension:

The SC10 4x4 belt is 5mm wide neoprene canvas backed. It will stretch slightly over its life, so the belt tensioners will

need to be adjusted from the initial settings after about 20-30 minutes of running. By touch, the belt should feel tight

when pressing on top surface between the pulleys, and you should only be able to depress the belt about 3mm or 1/8”.

After an initial run-in on the truck and setting the belt tension, you can verify that there is not excessive belt drag.

With the motor pinion removed, the truck should roll 10-15 feet with a slight push on level, smooth ground.

On the setup sheet, the tension slots are broken into 5 tension locations, with 3 being the middle. Since the rear pulley

is the drive, we will start with tension setting 3 in rear, and 4 in front. As the belt breaks-in, adjust the front tensioner

tighter until you are at the mid 3 setting. After that, any future tension adjustments to tighten the belt should be made

equally front and rear.

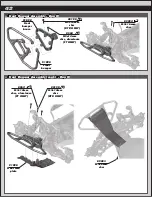

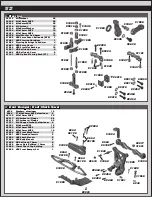

Belt Tension with 19 Tooth Front Over-Drive or Rear Under-Drive Pulleys:

WARNING:

Do not run the 19 tooth pulley for both front and rear. Only run one 19 tooth pulley on the truck at any time.

Changing the drive pulleys only affects front wheel speed. The drive speed of the rear wheels is fixed through the

gearbox. If you want to try the optional 19 tooth over-drive “O” front pulley OR 19 tooth under-drive “U” rear pulley, then

you will need to set the tensioner to setting 1 (tightest setting) on the end of the car with the smaller 19T pulley.

Then adjust the belt tension on the opposite pulley to get the proper overall tension (usually 3 or 2 tension setting on the

opposite gearbox). The Team recommend to start with the standard 20 tooth pulleys (equal drive) and then test the

alternate pulleys to determine which works best for you.

Front over-drive (“O” pulley in front) makes the front wheels turn faster than the rear, and gives the front end more drive

mid-to-exit. This can improve the steering feel in lower grip situations, or whenever you want more grip and steering.

Front under-drive (“U” pulley in rear) makes the front wheels turn slower than the rear, which can also help stabilize the

truck in certain conditions. You must dis-assemble the slipper clutch to change the rear pulley.

Tips for Beginners:

Before making any changes to the standard setup, make sure you can get around the track without crashing. Changes

to your vehicle will not be beneficial if you can’t stay on the track. Your goal is consistent laps.

Once you can get around the track consistently, start tuning your vehicle. Make only ONE adjustment at a time, testing

it before making another change. If the result of your adjustment is a faster lap, mark the change on the included setup

sheet (make adddtional copies of the sheet before writing on it). If your adjustment results in a slower lap, revert back to

the previous setup and try another change.

When you are satisfied with your vehicle, fill in the setup sheet thoroughly and file it away. Use this as a guide for future

track days or conditions.

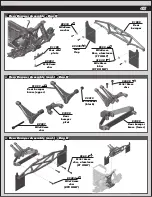

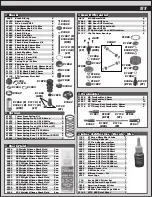

Motor Gearing Chart

Motor

Gear

Pitch

Pinion Spur (Final Drive Ratio) : 1

4.5 turn, 550 size

5.5 turn, 550 size

5.5 turn, 540 size

6.5 turn, 540 size

7.5 turn, 540 size

32

32

48

48

48

12

13

15

16

17

62

62

93

93

93

13.28

12.26

15.94

14.94

14.06

SC10 4X4 48 pitch

gear chart - 2.57:1

87

15

16

17

18

19

20

21

22

93

14.91

13.97

13.15

12.42

11.77

11.18

10.65

10.16

15.93

14.94

14.06

13.28

12.58

11.95

11.38

10.86

SC10 4X4 32 pitch

gear chart - 2.57:1

58

11

12

13

14

15

60

62

13.55

12.42

11.47

10.65

9.94

14.02

12.85

11.86

11.01

10.28

14.49

13.28

12.26

11.38

10.62

48