56

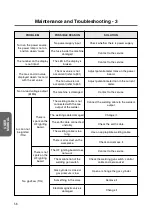

Maintenance and Troubleshooting - 3

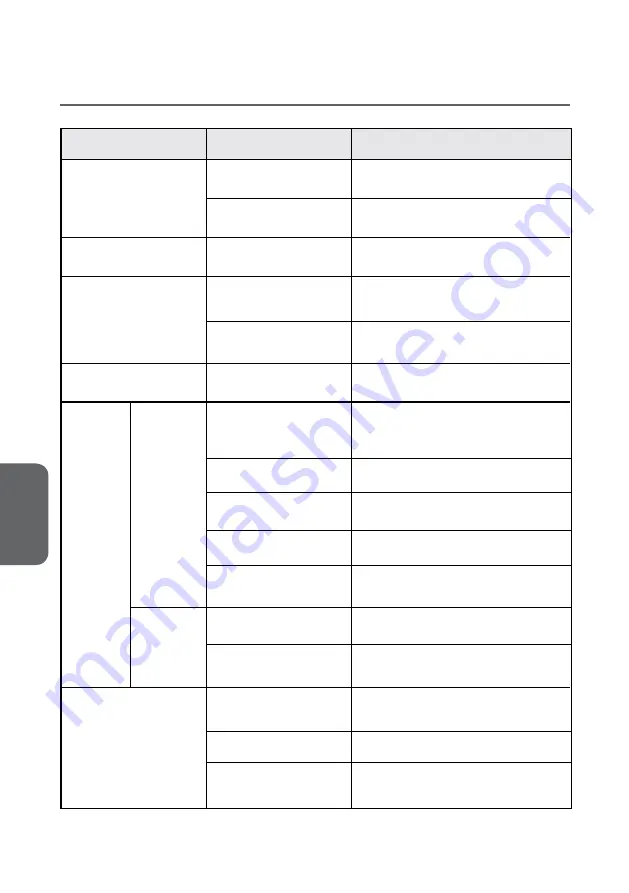

PROBLEM

POSSIBLE REASON

SOLUTION

No power supply input

The max value is not

accordant (refer to §3.1)

The min value is not

accordant (refer to §3.1)

The fuse inside the machine

damaged

The LED in the display is

broken

The earth cable connected

unstably.

There is oil or dust on the

workpiece.

The welding cable is too

long.

Arc can not

be ignited

(TIG)

There is

spark on the

HF igniting

board.

The machine is damaged

The welding cable damaged.

The welding cable is not

connected with the two

output of the welder.

Turn on the power source,

the power lamp is not on,

and fan doesn’t work

The max and min value

displayed doesn’t accord

with the set value.

The number on the display

is not intact.

No no-load voltage output

(MMA)

Check whether there is power supply

Adjust potentiometer Imax on the power

board.

Adjust potentiometer Imin in the current

meter.

Contact to the service.

Contact to the service.

Check the earth cable.

Check and remove it.

The malfunction of the

welding gun switch.

The HF igniting board does

not work.

There is not

spark on the

HF igniting

board.

Check the welding gun switch, control

cable and aero socket.

Contact to the service.

Use an appropriate welding cable.

Contact to the service.

Change it.

Connect the welding cable to the welder’s

output.

No gas flow (TIG)

Open or change the gas cylinder

Remove it

Change it

Gas cylinder is close or

gas pressure is low

Something in the valve

Electromagnetic valve is

damaged

U

S

E

R

MAN

U

AL

Summary of Contents for Inverter 205-TIG AC/DC

Page 2: ......

Page 38: ...36 KULLANIM KILAVUZU ...