Ascon Tecnologic - K__V - Indicators - ENGINEERING MANUAL - PAG. 17

8. OPERATIVE MODES

As we said at paragraph 4.1, when the instrument is powe-

red, it starts immediately to work according to the memori-

zed parameter value.

8.1 How to enter the “Operator Level”

The instrument is showing the “standard display”.

1.

Press the

button

2.

The instrument will show alternately the acronym of the

first parameter promoted to this level and its value.

3.

By

and

buttons assign to this parameter the desi-

red value.

4.

Press the

button in order to memorize the new value

and go to the next parameter.

5.

When you want to come back to the “standard display”

push the

button for more than 5 seconds.

Note:

The parameter modification of the Operator level

is subject to a time out. If no button is pressed for

more than 10 seconds, the instrument goes back to

the “standard display” and the new value of the last

selected parameter will be lost.

8.2 How to enter the “Limited Access

Level”

The instrument is showing the “standard display”.

1.

Press the

button for more than 5 seconds;

2.

The display will show alternately “PASS” and “0”;

3.

By

and

buttons set the value assigned to

[114] PAS2 (Level 2 password).

Notes: 1.

The factory default password for configuration

parameters is equal to 20.

2.

All parameter modification are protected by a

time out. If no button is pressed for more than 10

second the instrument comes automatically back

to the Standard display, the new value of the last

selected parameter is lost and the parameter

modification procedure is closed.

When you desire to remove the time out (e.g. for

the first configuration of an instrument) you can

use a password equal to 1000 plus the program-

med password (e.g. 1000 + 20 [default] = 1020).

It is always possible to manually End the parame-

ter configuration procedure (see below).

4.

Push

button.

5.

The instrument will show alternately the acronym of the

first parameter promoted to this level and its value.

6.

By

and

buttons assign to this parameter the desi-

red value.

7.

Press the

button in order to memorize the new value

and go to the next parameter.

8.

When you want to come back to the “standard display”

push the

button for more than 5 seconds.

8.3 How to see but not modify the

“Limited Access Parameters”

Sometime it is necessary to give to the operator the possibi-

lity to see the value assigned to the parameter promoted in

the Limited Access level but it is important that all changes

are made by autorized personnel only.

In this cases, proceed as follows:

1.

Press the

button for more than 5 seconds

2.

The display will show alternately “

PASS

” and “

0

”.

3.

By

and

buttons set the value -181.

4.

Push

button.

5.

The instrument will show alternately the acronym of the

first parameter promoted to the level 2 and its value.

6.

Using

button it is possible to see the value assigned

to all parameter present in level 2 but it will not be possi-

ble to modify it.

7.

It is possible to come back to the “standard display” by

pushing the

button for more than 3 seconds or by

pushing no pushbutton for more than 10 seconds.

8.3.1 Keyboard function when the instrument

is in display mode

Runs the action programmed by [116] uSrb

(

button function during RUN TIME) parameter.

Allows entry into parameter modification procedures.

Allows you to start the “Direct set point modification”

function (see below).

Allows you to display the “additional informations” (see

below).

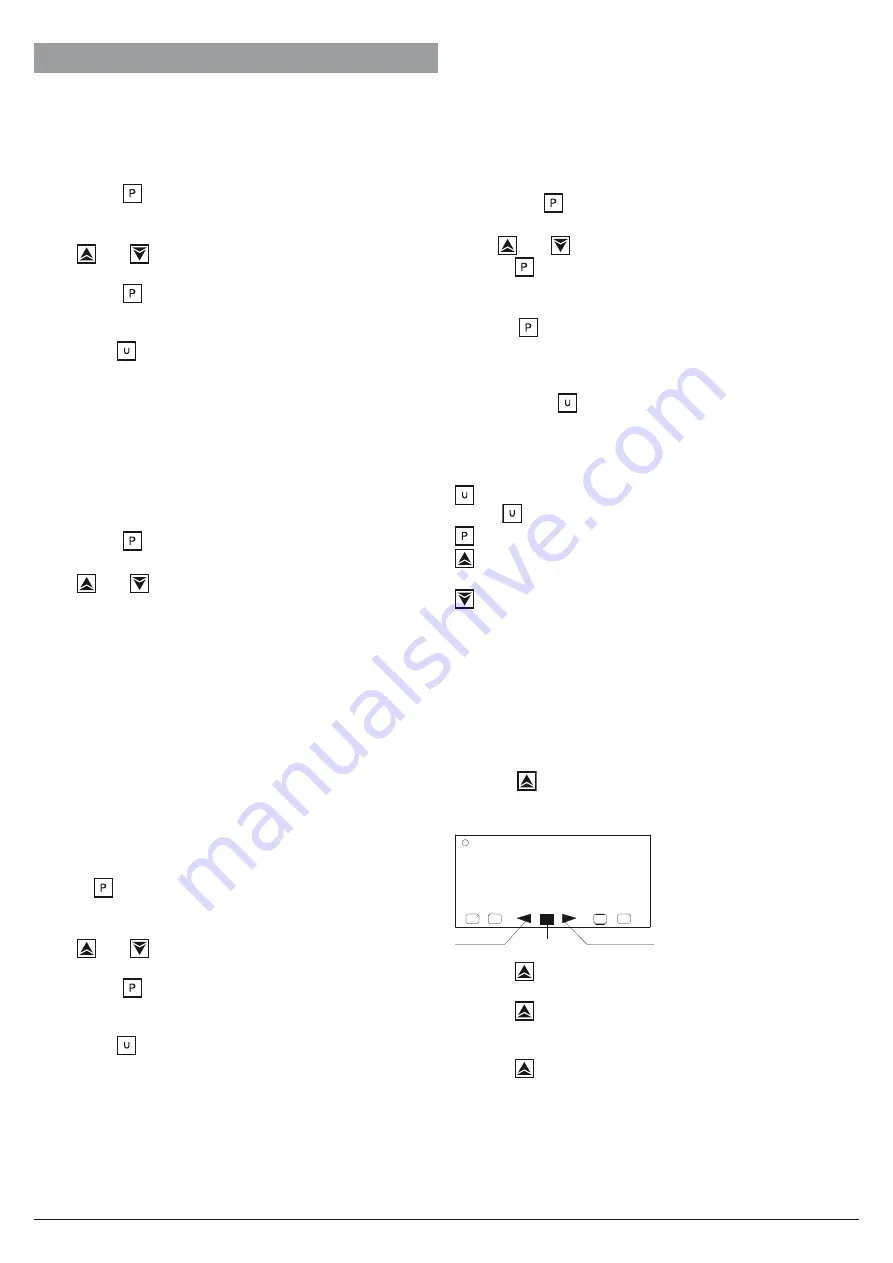

8.3.2 Additional informations

This instrument is able to show you some additional informa-

tions that can help you to manage your system.

The additional information is related to how the instrument is

programmed, hence in many cases, only part of this informa-

tion is available.

1.

When the instrument is showing the “standard display”

push

button.

The display will show the maximum measured value and

turn ON the “UP” LED

320.5.

UP LED

DOWN LED

Delta LED

2.

Push

button again. The display will show the mini-

mum measured value and turn ON the “down” LED

3.

Push

button again. The display will show the differen-

ces between the maximum and the minimum measured

value and turn ON the “delta” LED.

4.

Push

button again. The display will show:

- “

h

” followd by the worked hours or

- “

d

” followed by the worked days

according to the [67] co.tY parameter setting.