Transporting ASCO Load Banks

ASCO Sigma LT load banks will vary in weight depending on the model. Make sure you

check the load bank name plate for the correct weight. Sigma LT load banks have fork lift

pockets and/or castors. Only lift from the forklift pockets and no where else.

Lifting by forklift truck

Check the specifications to ensure that the forklift truck has sufficient capacity to safely

lift the weight. Add 5% to the specified weight for minimum packing, and 15% for a unit in

an export wooden case.

Protection and securing on transport

If a load bank is carried on an open goods vehicle, it should be covered with a tarpaulin, or

a similar to stop the wind from driving the fan.

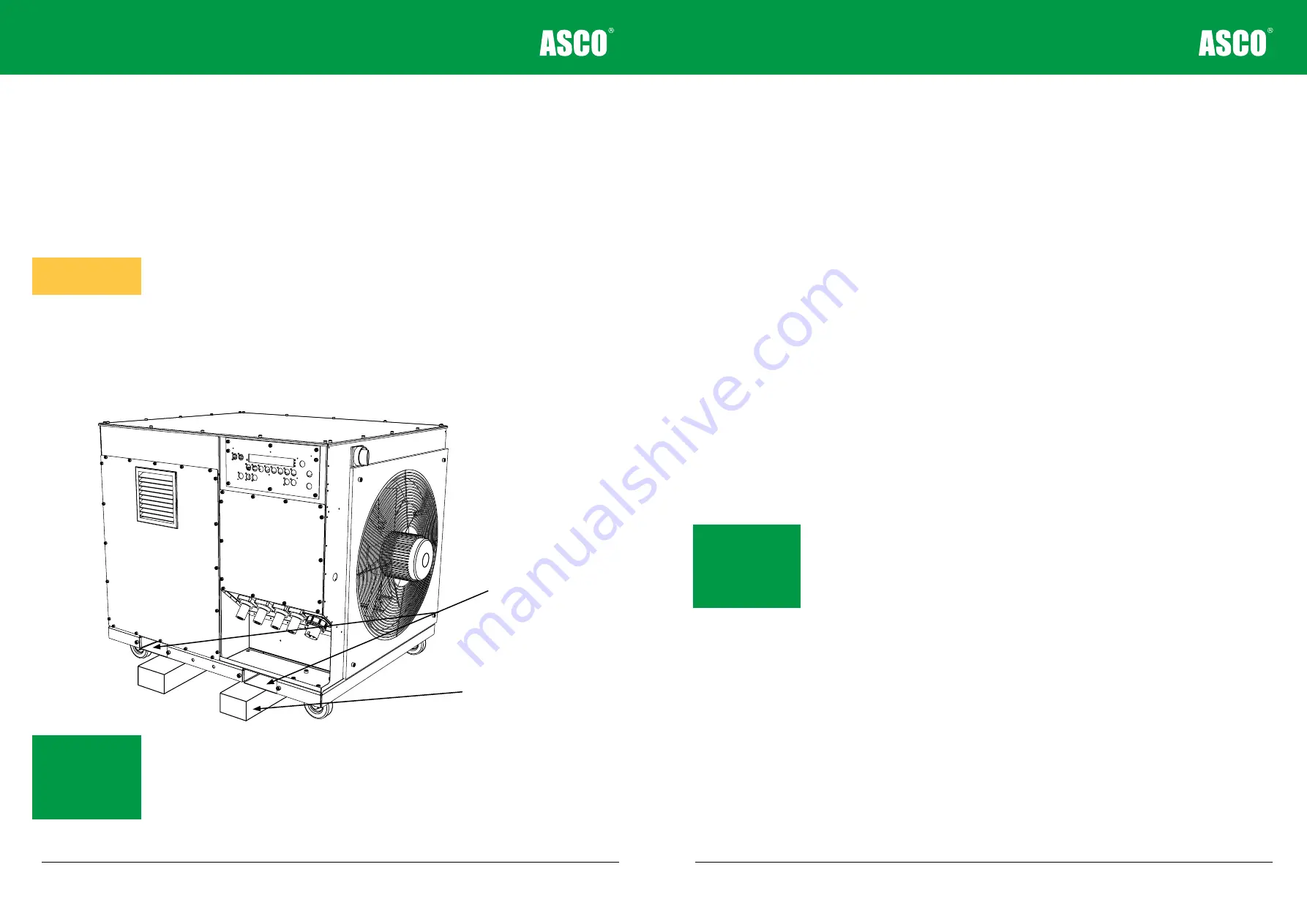

Figure 2-1

Castor-mounted load banks should be supported off the castors and firmly fixed

down

2 - 4

Note:

Do not tie straps

over the top of the load

bank. The tie-down

should be made through

the pockets in the fork-

lift pocket base only.

Castor mounted load banks

should be supported off of the

castors during transport. Use

wooden blocks for this purpose.

Use the forklift pockets to

tie down the load bank

2 - 5

Setting up ASCO Sigma LT Load Banks

There are a number of factors that need to be considered before you select a load bank

for a particular application. Obviously it is important to ensure that the load bank has

sufficient electrical capacity to test the supply, but you also need to ensure that it can

operate correctly and safely in the position you have chosen.

Location

The first thing to decide when setting up a load bank is where the unit is to be located. You

need to consider the following to ensure that the unit can be operated safely:

Environment.

Sigma LT load banks are designed for indoor use only. A standard Sigma

LT load bank can be used in an ambient temperature between -10°C and +40°C, at 90%

relative humidity (non condensing), and at altitudes up to 1000m above sea level.

Loading.

The load bank is heavy and must be setup on a level surface that is capable of

supporting its weight (see nameplate).

Space.

There must be sufficient space to provide access for maintenance to all of the

panels and the protective inlet and outlet grilles. There must be at least one metre of clear

space on the air intake side of the load bank (the fan side) and five metres of clear space

on the air outlet side. See the appendices of this manual for the specific requirements of

individual units.

Airflow requirements.

When it is operating a Sigma LT load bank can require up to 10 m

3

of cooling air per second. As it passes through the unit, the air becomes hot enough to

provide a risk of fire or personal injury.

When setting up the unit you need to make sure that there is adequate air available, that

it can be discharged safely, and that there is no risk that the hot air will recirculate to the

air intake of the unit.

Note:

If necessary,

a barrier should be

erected around the hot

air outlet to prevent any

possibility of personal

injury.

Warning! Avoid walking

on the roof of the unit.

Chapter Two

Load Bank Setup