GRINDER MIXER ADJUSTMENTS

25

GRINDER MIXER ADJUSTMENTS

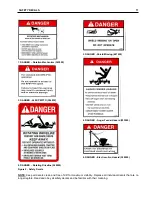

CAUTION: DO NOT MAKE ANY

ADJUSTMENTS WHILE THE MACHINE

IS

IN

OPERATION

AUGER/SUPPLEMENT.

D

RIVE

C

HAIN

A

DJUSTMENTS

The mill to mixer auger/supplement hopper drive

chain and the discharge auger drive chain are

tensioned with an idler sprocket (See Figure 34).

Adjust the chain tension to 1/2 inch total deflection

by positioning the idler sprocket.

Figure 34 - Mill to Mixer Auger Drive Chain.

M

AIN

D

RIVE

C

HAIN

Adjust the tension of the main drive chain by

loosening the idler roller and bolt, and then sliding

the idler sprocket toward the chain. (See Figure 35)

Re-tighten the idler roller bolt and make sure the

chain deflection is ½ inch total at the longest span

NOTE: The chain should be checked and oiled

daily.

Figure 35 - Drive Chain Adjustment (Shields

Removed for Clarity).

M

AIN

D

RIVE

B

ELTS

Belts on the new machines have been properly

tensioned at the factory. To re-tension the belts on

a machine which has been in operation.

•

Loosen bolts “B” and “C”. (See

•

Place a scale at the midway point of the

double v-belts on the pulleys.

•

Adjust bolt “A” (See

) until 15

pounds of pull on the scale raises the top

of one double v-belt approximately ¼ inch

above the top of the remaining belts. (See

Figure 36 - Belt Tension Adjustment (Shields

Removed for Clarity).

•

All 4 belts should have the average of ¼

inch deflection at 15-18 pounds.

•

Loosen bolts “E” and “F”. (See

•

Loosen idler bolt “G”

•

Adjust bolt “H” until Hammer mill Jack

Shaft “D” is parallel to Hammer mill

Housing. Measure both sides

•

Tighten bolts “B”, “C”, “E”, and “F”. Lock

adjusting bolts “A” in place with nut.

•

Adjust tension in Main Drive Chain. (See

Previous Section)

Figure 37 - Belt Tension Adjustment Bearing Mount.

½”

A

B

C

F

E

H

G

D