No matter which of the options below you choose for a base, an ARROW ANCHORING KIT is

recommended as an eff ective method of properly securing your building after assembly is complete.

OPTION 1: Directly on ground (earth)

Assemble your building directly on level ground (grass, dirt, rock, sand, etc.). If you choose this option Arrow has a simple kit available to

provide a fl oor inside the shed to keep stored items off the ground. This kit can be used to support a plywood fl oor (wood not included)

or be fi lled with sand/rock to provide a solid surface. (Order No. FB5465)

Allow 1 - 2 hours for construction.

OPTION 2: Wood Platform

If you decide to build your own base, be sure to select the appropriate materials.

These are the recommended materials for your base:

2 x 4's (38 mm x 89 mm) Pressure Treated Lumber

5/8" (15,5 mm) 4 x 8 (1220 mm x 2440 mm) Plywood-exterior grade NOTE: Pressure Treated Lumber must not be used where it

will make contact with your storage building. The properties of Pressure Treated Lumber will cause accelerated corrosion.

If Pressure Treated Lumber comes in contact with your storage building your warranty will be voided.

10 & 4 penny Galvanized Nails Concrete Blocks (optional)

The platform should be level and fl at (free of bumps, ridges etc.)

to provide good support for the building. The necessary materials

may be obtained from your local lumber yard.

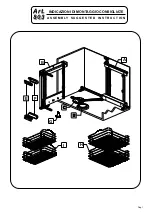

To construct the base follow instructions and diagram.

Construct frame (using 10 penny galvanized nails)

Measure 16"/24" (40,6 cm/61,0 cm) sections to construct

inside frame (see diagram)

Secure plywood to frame (using 4 penny galvanized nails)

Allow 6 - 7 hours for construction.

OPTION 3: Concrete Slab

The slab should be at least 4" (10,2 cm) thick. It must be level and fl at to provide good support for the frame.

The following are the recommended materials for your base.

1 x 4's (19 mm x 89 mm) (will be removed once the concrete cures)

Concrete Sheet of 6 mil plastic

We recommend for a proper strength concrete to use a mix of:

1 part cement 3 parts pea sized gravel 2 1/2 parts clean sand

Prepare the Site/Construct a Base

1. Dig a square, 6" (15,2 cm) deep into the ground (remove grass).

2. Fill up to 4" (10,2 cm) in the square with gravel and tamp fi rm.

3. Cover gravel with a sheet of 6 mil plastic.

4. Construct a wood frame using four planks of 1x4 (19 mm x 89 mm)

lumber.

5. Pour in concrete to fi ll in the hole and the frame giving a

total of 4" (10,2 cm) thick concrete. Be sure surface is level.

Allow 3 - 5 hours for construction and a week for concrete curing time.

57"

144,8 cm

45 7/8"

116,5 cm

The Base For Your Building

FRONT

(DOOR)

FRONT

(DOOR)

Base

BI09

Note: Finished Slab dimensions, with lumber removed.

Note: Platform/Slab will extend 9/16" (1,4 cm) beyond fl oor

frame on all four sides. Seal this 9/16" (1,4 cm) of wood with a

roofi ng cement (not included), or bevel this 9/16" (1,4 cm) of

concrete when pouring, for good water drainage.

16"/24"

40,6 cm/61,0 cm

9

57"

144,8 cm

45 7/8"

116,5 cm

We recommend that you purchase accessory items from your local storage building dealer whenever possible;

however, because the full line of accessories is not always available from all dealers, Arrow is off ering them

to you on a direct basis.

There are two ways to order Arrow Storage Building Accessories:

SPECIAL NOTE:

If your accessory is shipped via truck line a day time phone number is required to arrange delivery. If no

one is available to sign for the delivery, you may be subject to a re-delivery charge assessed by the carrier.

ORDERING ACCESSORIES....

A08

02/13

Option 1

Accessories can be purchased

through

arrowsheds.com

Option 2

Order accessories by telephone

using your MasterCard or Visa credit card.

Call toll free 1-800-851-1085

(Customer Service).

Allow 2 weeks for delivery.

Summary of Contents for BW54-A

Page 2: ......

Page 13: ...Assembly by Key No BI13 13...