Page 9 of 18

Issue 1324

507120-01

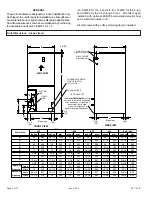

Supply and return duct system must be adequately sized

to meet the system’s air requirements and static pressure

capabilities. The duct system should be insulated with

a minimum of 1” thick insulation with a vapor barrier in

conditioned areas or 2” minimum in unconditioned areas.

Supply plenum should be the same size as the flangedopening

provided around the blower outlet and should extend at

least 3 ft. from the air handler before turning or branching

off plenum into duct runs. The plenum forms an extension

of the blower housing and minimizes air expansion losses

from the blower.

INSTALLING DUCT SYSTEM

Install the conditioned air plenum, ducts and air filters (not

provided) in accordance with NFPA 90B Standard for the

Installation of Warm Air Heating and Air-Conditioning

Systems (latest edition).

Connect supply air duct to the flange on top of the air handler.

If an isolation connector is used, it must be nonflammable.

A return air duct system is recommended. If the unit is

installed in a confined space or closet, a return connection

must be run, full size, to a location outside the closet.

Connecting Refrigerant Lines

Refrigerant lines must be connected by a qualified technician

in accordance with established procedures.

1.

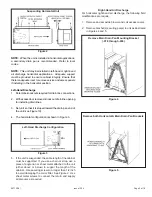

Route the suction and liquid lines from the fittings

on the indoor coil to the fittings on the outdoor unit.

Run the lines in as direct a path as possible avoiding

unnecessary turns and bends.

2. Make sure that the suction line is insulated over the

entire exposed length and that neither suction nor liquid

lines are in direct contact with floors, walls, duct system,

floor joists, or other piping.

3. Connect the suction and liquid lines to the evaporator

coil.

4. To avoid damaging the rubber grommets in the cabinet

while brazing, slide the rubber grommets over the

refrigerant lines until they are away from the heat

source.

5. Braze using an alloy of silver or copper and phosphorus

with a melting point above 100°F.

NOTE:

Do not use soft solder.

6. Reinstall the rubber grommets after brazing is finished.

7. Make sure outdoor unit has been put in place according

to the Installation Instructions and is connected to the

refrigerant lines.

Sealing the Unit

Seal the unit so that warm air is not allowed into the cabinet.

Warm air introduces moisture, which results in water blow-

off problems. This is especially important when the unit is

installed in an unconditioned area.

Refrigerant lines must be clean, dehydrated, refrigerant-

grade copper lines. Air handler coils should be installed

only with specified line sizes for approved system

combinations.

Handle the refrigerant lines gently during the installation

process. Sharp bends or possible kinking in the lines

will cause a restriction.

Do not remove the caps from the lines or system

connection points until connections are ready to be

completed.

IMPORTANT

There must be an airtight seal between the bottom

of the air handler and the return air plenum. Use

fiberglass sealing strips, caulking, or equivalent sealing

method between the plenum and the air handler

cabinet to ensure a tight seal. Return air must not

be drawn from a room where this air handler or any

gas-fueled appliance (ie., water heater), or carbon

monoxide-producing device (ie., wood fireplace) is

installed.

WARNING

When sealing the cabinet, be sure to seal closed any

space around the holes where the drain lines exit the

cabinet using duct tape and/or Permagum. Warm air

must not be allowed to enter through any gaps or holes

in the cabinet.

IMPORTANT

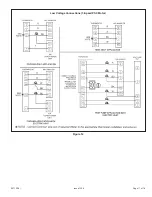

Unit Air Filter Size Chart

Model

Nominal Filter Size

-018

12” X 20” X 1

-024

15” X 20” X 1

-036

18” X 20” X 1

-042,-048 and -060 18” X 24” X 1