Page 5 of 18

Issue 1324

507120-01

NOTE:

When the unit is installed in horizontal applications,

a secondary drain pan is recommended. Refer to local

codes.

NOTE:

This unit may be installed in left-hand or right-hand

air discharge horizontal applications. Adequate support

must be provided to ensure cabinet integrity. Ensure that

there is adequate room to remove service and access panels

if installing in the horizontal position.

Left-Hand Discharge

1. Determine knockouts required for drain line connections.

2. With access door removed, knock out drain line opening

for installing drain lines.

3. Set unit so that it is sloped toward the drain pan end of

the unit (see Figure 10).

4. The horizontal configuration is shown in Figure 3.

5. If the unit is suspended, the entire length of the cabinet

must be supported. If you use a chain or strap, use a

piece of angle iron or sheet metal attached to the unit

(either above or below) to suppor the length of the

cabinet. Use securing screws no longer than 1/2 inch

to avoid damaging the coil or filter. See Figure 2. Use

sheet metal screws to connect the return and supply

air plenums as required

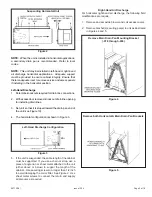

Right-Hand Air Discharge

For horizontal right-hand air discharge, the following field

modifications are require.

1. Remove and set aside blower and coil access covers.

2. Remove brachet(s) securing pan(s) to unit as illustrated

in Figures 4 and 5.

Figure 5

Remove both Horizontal & Main Drain Pan Brackets

Suspending Horizontal Unit

Figure 2

Figure 3

Left-Hand Discharge Configuration

Figure 4

Remove Main Drain Pan Mounting Bracket

(-018 through -036)