Issue 1324

507120-01

Page 12 of 18

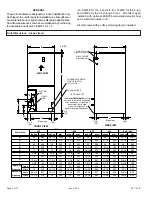

Airflow - Cooling Blower Speed

The cooling blower speed is factory configured to provide

correct airflow for an outdoor unit that matches the maximum

cooling capacity rating of the air handler.

If the outdoor unit is smaller than the maximum cooling

capacity rating for the air handler, the cooling blower speed

may need to be changed. Refer to blower performance

chart, Table 2.

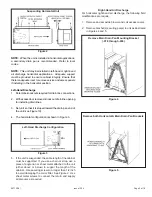

1. Disconnect all power supplies.

2. Remove the air handler access panel.

3. Locate pin number 2 on the blower relay. Two black

wires are connected to this terminal pin. One connects

to pin number 5 on the blower relay, one connects to an

in-line splice connecting to a red wire.

4. Remove the wire going to the 4-pin blower motor

connector from the splice.

5. Connect the blower lead [Red (La), Black (HI)] onto the

splice from the 4-pin blower motor connector.

NOTE:

Reuse the factory-installed plastic cap on whichever

wire is not used.

6.

Replace all panels.

7. Reconnect power.

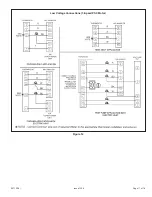

CHANGE BLOWER SPEED

NOTE:

Refer to wiring diagram located on the unit access

panel and blower performance (Table 2).

•

All air data measured external to unit with 1 inch non-

pleated air filter in place.

•

All factory settings are medium speed except the -48

which is set to low speed from the factory.

•

All data given while air handler is operating with a dry

DX coil.

Blower Performance (3-Speed PSC) -240V (CFM @ ESP. -in. w.c.)

•

Blower Performance (CFM vs. ESP inches H2O)

•

Cooling speeds should not be reduced below factory setting.

•

Units with electric heat approved at 0.5” maximum and medium blower speed minimum.

•

Downflow units should be set to high speed minimum.

•

Different speeds can be set for heating mode.

ELECTRIC SHOCK HAZARD!

Disconnect all power supplies before

servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

WARNING