ARITERM SWEDEN AB

Installation, Operation and Maintenance - 2007.10.26- 6/12

Th

e boiler shall be positioned and installed according to the building rules in force.

Before installing the boiler, the chimney must be controlled for underpressure and

possible risk of condensation. It is possible that an air draught compensator has to be

installed. Inner pipe is recommended for minimizing the risk of condensation.

Space needed for installation: Minimum clearance in front of the boiler (burner

included) is 1000 mm. Clearence on the top shall be at least 0,5 m. By the other side

of the boiler clearence shall be at least 0,8 m. Th

e boiler must be level. If the fl oor is

uneven, adjustments can be made with the help of four adjusting bolts (enclosed with

the boiler) that shall be fi tted to the bottom plate of the boiler.

Th

e air intake duct to the boiler room must have at least the same area as the fl ues.

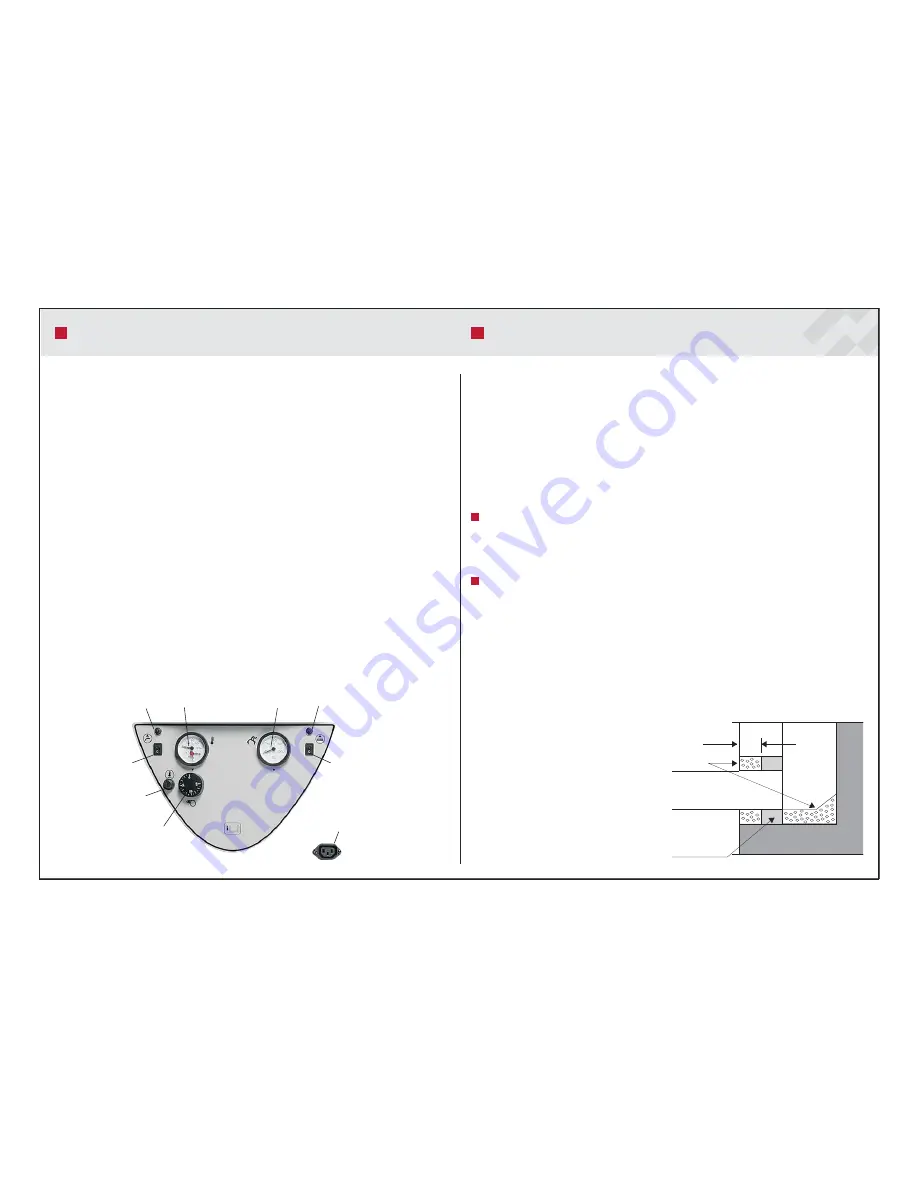

Chimney installation

To embed the angular tube in the chimney, proceed according to the drawing below.

If the tube is embedded as described, you will be able to avoid soot leakage when the

chimney is being swept.

Flue connection and combustion air intake

Th

e combination fl ue of the boiler allows for connection towards the top as well as

to the rear. Boiler cement is suitable for sealing. Recommended fl ue gas requirements

for B 50: brick chimney lined with a Ø 150 mm acid proof thin-walled tube

or an acid proof Ø 150 mm element chimney. Recommended underpressure in the

chimney is 25 Pa. Th

e height of the gas fl ue shall be dimensioned according to the

building’s requirements, but should be at least 6 m. If condensation water comes out of

the fl ue, a condensate drain pan shall be installed in the lower portion of the chimney.

Th

e combustion air intake must not be covered.

1. Regulating thermostat

Adjustment of operating temperature for pellet burner

2. Overheating protection, burner

- Press the button to reset the overheating cut-out. Before reset,

check that there is water in the boiler and that the operating thermostat

works correctly. If you cannot reset the overheat protection, please

contact a qualied installation contractor.

3. Th

ermometer / Pressure gauge

- Shows water pressure and water temperature at the top of the

boiler. Due to the stratication of water, boiler temperature varies

considerably within the boiler; the lowest water temperature is measured

at the bottom and the highest at the top.

4.

Flue gas thermometer

- Displays temperature of leaving fl ue gases at the fl ue connection

point.

5. Automatic fuse

- Automatic fuse, circulation pump, external heating circuit.

6.

Switch

- Switch, circulation pump, external heating circuit.

7.

Automatic

fuse

- Automatic fuse, circulation pump, external hot water circuit.

8.

Switch

- Switch, circulation pump, external hot water circuit.

9. Connection for external auger

CONTROL PANEL

INSTALLATION

30

Mortar

Flue pipe

30 mm incom-

bustible

insulation

ATTENTION! The chimneysweep must be

notied for inspection of the

fl

ue.

CAUTION! The boiler has low

fl

ue gas

temperatures, which, under certain

conditions,might lead to condensation of

fl

ue gases.

1

2

3

4

5

7

9

8

6