5

ERT7 and ERT8 Ebbert Rivet Tools (HK1061

)

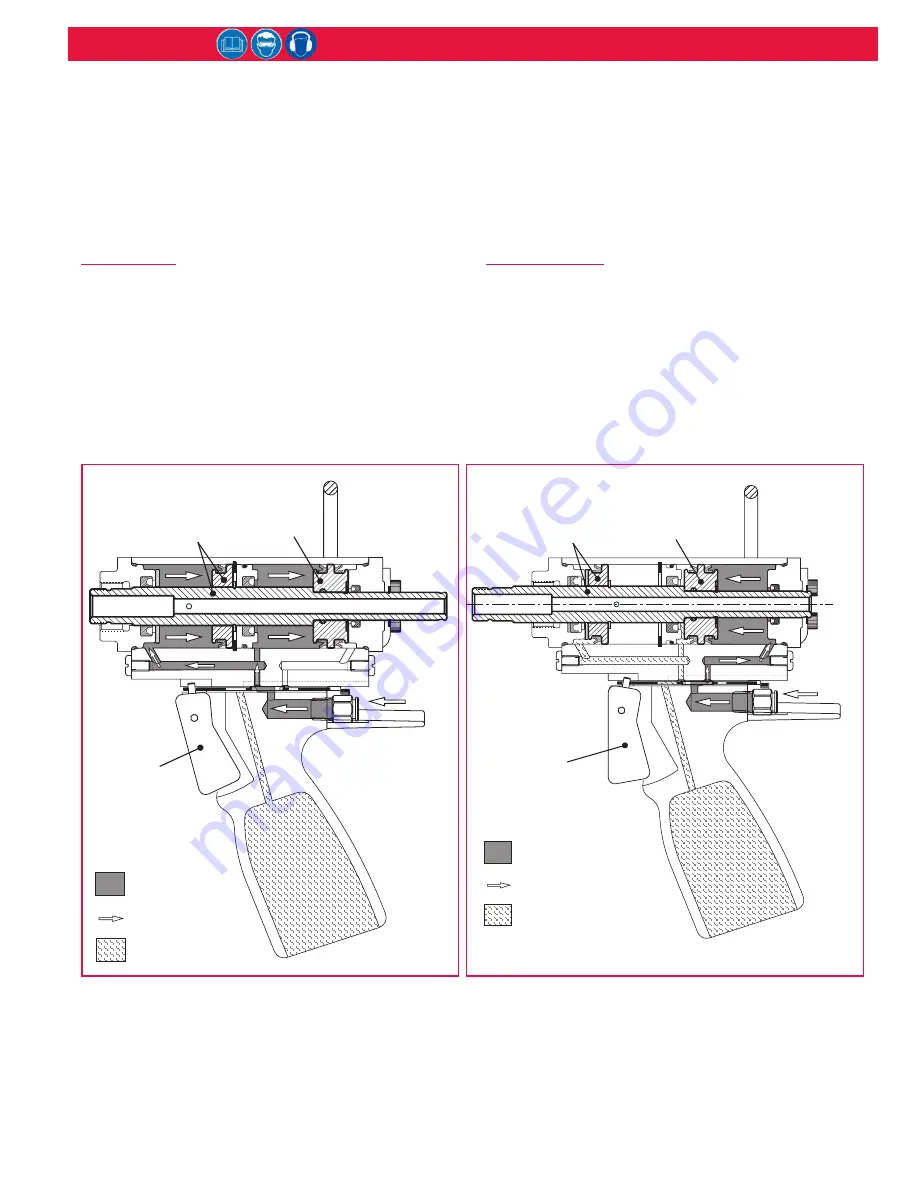

PULL CYCLE

When the trigger is pressed, the incoming non-oiled

plant air, regulated at 90 psi forces the Piston Assembly

and Double Piston to the rear of the tool, and air is

exhausted out the bottom of the tool. The fastener is

installed, and the fastener pintail breaks off.

NOTE

:

The ERT8 exhaust air exits through small holes

in the bottom of the Valve Body. (See Item 16 of ERT8

Assembly Drawing in this manual.)

RETURN CYCLE

When the trigger is released, the pressurized air is

directed to the rear of the pistons, causing them to move

forward. The fastener pintail is vacuumed out the rear

of the tool and into the Power Unit Pintail Collection bin,

and the tool is ready for the next fastener installation.

This manual contains operating and service procedures

for the Ebbert Rivet Tool models ERT7 and ERT8. Pay

close attention to the recommended service procedures

in this manual.

Specific instructions for each tool are given under that

tool model number heading. While the tools appear

similar, each tool contains parts not used on other

models, and removal and replacement methods may

vary.

General Information

Principle of Operation