Use and maintenance handbook

Page 15

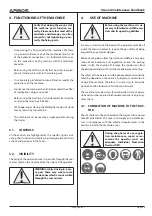

3. FUNCTIONING OF THE MACHINE

Verify that during the work, all of

the machine parts function cor-

rectly. Please note that most of the

accidents and damages are often

caused for not tightening up cor-

rectly the fixing parts.

•

Since during the first period of the machine’s life there

is a general settlement of all the mechanical parts and

of the hydraulic connections, it is fundamental to carry

on the inspections on the machine with the maximum

precision.

•

Before using the machine, verify that no animals or peo-

ple are standing in or within the working area.

•

It is absolutely prohibited to take off and/or modify the

protections on the machine.

•

Do not use the machine when ill, tired or under the effect

of medications, drugs or alcohol.

•

Before using the machine, it is fundamental learning the

controls panel and their function.

•

While opening or closing the folding frame, do not stand

for any reason by the machine.

•

The machine must be used by a single operator driving

the tractor.

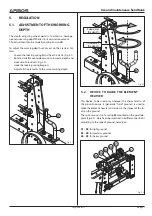

3.1. CONTROLS

All the controls are highlighted by the specific signals indi-

cating their function and explaining through pictorials their

actions and positions in the cabin.

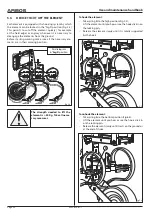

3.2. VISIBILITY

Checking of the operation areas is possible through the rear

mirrors sited on the tractor and by the sight of the operator.

WARNING- while driving in rever-

se gear there may create some

shade zones which are not visible

through the rear mirrors.

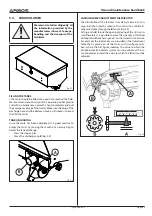

4.

USE OF MACHINE

Before using the machine, it is ne-

cessary to familiarize with the con-

trols and its operating abilities.

In every circumstance the body of the operator must be all

inside the cabin, in order to reduce the possibility of being

exposed to any external dangers.

Before coming down from the tractor and before every ope-

ration of maintenance and regulation, action the parking

brake, switch the engine off, remove the ignition key from

the dashboard and wait for all the mobile elements to stop.

The safety of the operator and the people present around the

machine depends on the ability of judgment and caution in

using of the machine. Therefore, it is necessary to know the

position and the functions of all the controls well).

The machine must be always found in perfect state of opera-

tion and must be repaired with replacement parts only origi-

nates them.

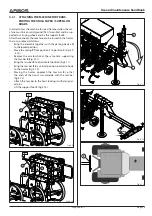

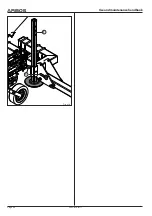

4.1. CONNECTION OF MACHINE TO THE TRAC-

TOR

The machine must be connected to the tractor with a power

take off activated at 500 rpm, with weight and suitable po-

wer, in compliance with the enforced requirements in the

country in which the machine is uses.

During the phases of use, regula-

tion, maintenance, repair or mo-

vement the operator must use

adequate Individual Protection

Devices (DPI).

Summary of Contents for Unica Super

Page 2: ......

Page 4: ...www matermacc it Use and maintenance handbook...

Page 16: ...www matermacc it Use and maintenance handbook Page 12...

Page 24: ...www matermacc it Use and maintenance handbook Page 20 F 5 Fig 4 14...

Page 34: ...www matermacc it Use and maintenance handbook Page 30...

Page 36: ......

Page 37: ...Use and maintenance handbook...