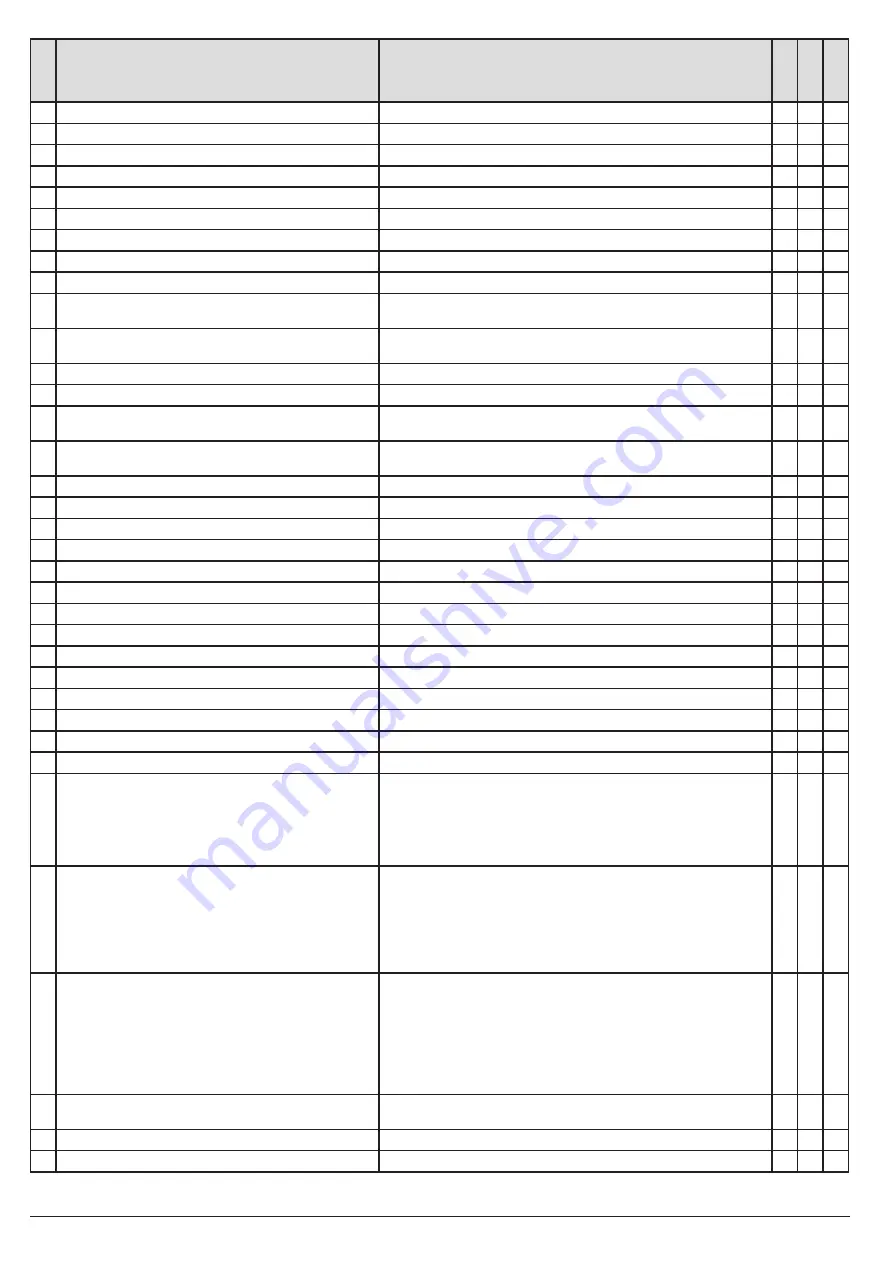

8

#

Menu

Description

Oper

at

or

Mana

g

er

Tec

hnician

4

Sensor > Maintenance > Cleaning status Sens

Function Enabling/Disabling the cleaning of sensor reading heads.

l

l

l

5

Alarms > Min. flowrate

Minimum flowrate value under which the relevant alarm is activated

l

l

6

Alarms > Max. flowrate

Maximum flowrate value above which the relevant alarm is activated

l

l

7

Options > Language

Language of the display.

l

l

8

Options > Units of measurement > Flowrate

Flowrate units of measurement.

l

l

9

Options > Units of measurement > Volume

Volume units of measurement.

l

l

10

Options > Display contrast

Display contrast.

l

l

l

11

Options > Alarm tones

Enabling/disabling of alarm tones.

l

l

12

Options > Keytones

Enabling/disabling of keytones.

l

l

l

13

Options > Screen Settings

(visible only if “Volume Counter” operating mode is selected)

Setting of the position used to display the data in the current screen: “Flowrate”

– “Tot 1 volume” – “Tot 2 volume”

l

l

14

Options > Valve inter. time

(visible only in Operating mode "Filling check [F]")

Time between valve closing signal and valve actual closing.

l

15

Options > Operating mode

Set operating mode

l

16

Options > User access

Selected access level

l

l

l

17

Setup management > Load

Loads the settings from a USB pendrive (

requires the intervention of a skilled

technician

)

l

18

Setup management > Save

Saves the settings from a USB pendrive (

requires the intervention of a skilled

technician

)

l

19

Diagnostics > Display properties > Firmware version

Display firmware version (display-only)

l

l

l

20

Diagnostics > Display status > Display test

Display operation test

l

l

l

21

Diagnostics > Display status > Key test

Key operation test

l

l

l

22

Diagnostics > Sensor properties > Sensor name

Name of the sensor (display-only)

l

l

l

23

Diagnostics > Sensor properties > Serial number

Sensor serial number (display-only)

l

l

l

24

Diagnostics > Sensor properties > Hardware version

Sensor Hardware version (display-only)

l

l

l

25

Diagnostics > Sensor properties > Software version

Sensor Software version (display-only)

l

l

l

26

Diagnostics > Sensor properties > Fw. version Boot.

Sensor Bootloader Firmware version (display-only)

l

l

l

27

Diagnostics > Sensor properties > Node ID

Flowmeter identification number (ID) when connected to a CanBus network

l

28

Diagnostics > Sensor status > Temperature

Sensor internal temperature

l

l

l

29

Diagnostics > Sensor status > Batt. Power supply

Power supply voltage detected by the sensor

l

l

l

30

Diagnostics > Sensor status > Flowrate

Detected instant flowrate

l

l

l

31

Diagnostics > Sensor status > Conductivity 1

Liquid conductivity detected by electrode no.1

l

l

l

32

Diagnostics > Sensor status > Conductivity 2

Liquid conductivity detected by electrode no.2

l

l

l

33

Diagnostics > Sensor status > Status details

Sensor status details displaying:

- No Err. Detec. / Error detected

- Measurement active / Measurement In stand-by

- No flowrate / Flowrate detected

- No liquid / Liquid present

- Filling disabled / Filling Enabled

l

l

l

34

Diagnostics > Sensor status > Error list

Displaying of detected errors:

- None

- Wrong calibration

- Voltage out of limit!

- High temperature!

- Unstable reading

- Hw errors detected"

l

l

l

35

Diagnostics > Sensor status > Hw error list

Displaying of detected hardware errors:

- None

- Current error

- VBoost error

- VMag error

- 5V error

- 3.3V error

- System start error

l

l

l

36

Device Management > Sensor Fw update

Sensor firmware update through USB pendrive (

requires the intervention of a

skilled technician

)

l

37

Device Management > Sensor setting Reset

Sensor default data reset

l

38

Device Management > Display setting Reset

Display default data reset.

l