22

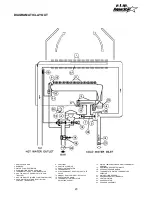

DESCRIPTION OF OPERATION OF AQUASTAR 80/125 MODELS

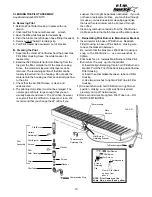

WATER PATH

Cold water entering the Cold Water Inlet passes through

a nylon mesh Water Filter Screen (#21) which filters out

dirt and debris. Water then passes through the Water

Flow Restrictor (#8) which prevents water flow from

exceeding 3.25 gallons per minute. The flow control is

there to help ensure that water does not flow through the

heat exchanger faster than the burners can heat it. The

restrictor can be removed if needed.

From the Flow Restrictor the water moves up to #3, the

Water Flow Sensor. This entire unit is also known as the

Water Valve Assembly. The spring pressure of the

Venturi Piston (#23) diverts most of the water flow into the

diaphragm chamber. The only way out of the diaphragm

chamber is through a smaller hole, the venturi. Water

squirting through the venturi creates a pressure buildup

on the high pressure side of the diaphragm chamber. The

water pressure is lower on the other side of the venturi

hole. A small tube transfers this reduced pressure to the

low pressure side of the diaphragm chamber.

The pressure differential moves the diaphragm which

exerts force on the Push Rod (#25). At 3/4 gallons per

minute, the pressure differential becomes sufficient to

overcome the spring pressure of the Gas Flow Valve (#7)

opening the gas valve.

The water then moves through the Heat Exchanger (#1)

where it absorbs approximately 80% of the heat from the

burners. The balance of the heat is exhausted with the

flue gases. Located midway through the Heat Exchanger,

a Water Temperature Probe (#17) senses water

temperature. It works with the Gas Flow Valve (#6) to

regulate the amount of gas to the burners.

Before the water leaves the Heat Exchanger it passes the

Overheat Sensor Switch (#19). This is a safety device

which causes other gas controls to shut off all the gas

if the Heat Exchanger overheats.

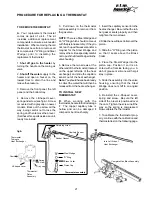

GAS FLOW PATH

The appliance Gas Regulator (#24) at the inlet to the

heater ensures that gas pressure fluctuations don’t over-

pressure the heater. The Manual Gas Flow Shut-off

Valve (#14) provides a quick gas shut off right on the

heater.

The gas shut-off safety devices are integrated with the

pilot light. An Electro-Magnet in the Gas Valve ensures

that gas flows to the burner only when there is a pilot light

to ignite it. The Pilot Knob (#15) shuts gas off to the

burners while you light the pilot. You must hold the Pilot

Knob in at the single flame position long enough for it to

heat the Thermocouple (#12).

The water activated gas valve (#7) opens and shuts in

response to water flow. On heaters fueled with LP Gas,

a Slow Ignition Device (#4) gradually increases gas flow

for ignition. The Natural Gas models have no such device

because Natural Gas is delivered at a much lower

The Thermocouple (#12) produces a very small amount

of electricity (0.03 volts) when it is exposed to a flame.

This electricity is just enough to hold open the spring-

loaded Electromagnet Gas Flow Shut-off Valve (#13). If

the thermocouple is not hot enough, the spring closes the

valve. Pushing #15 in the single flame position, allows

gas to flow to the pilot. Gas can’t go to the burners until

the pilot has been lighted and the knob has been turned

to the three flame position and released.

If a malfunction causes the Heat Exchanger to get too

hot, the Overheat Sensor Switch (#19) interrupts the

electrical circuit between the thermocouple and

electromagnet. This safety feature shuts off the gas to

both burners and the pilot. Manual relighting is required

once the problem is corrected.

The Thermostatic Gas Flow Modulator (#5) works with

the Water Temperature Probe (#17) to modulate the

amount of gas delivered by the thermostatically controlled

Gas Flow Valve, (#6). Initially the water in the Heat

Exchanger is cold, the Gas Flow Valve allows a full flow

of gas to the Burners (#2). Then depending on the flow

rate, inlet water temperature and/or the Thermostatic

Temperature Selector (#20), the Gas Flow Valve (#6)

adjusts gas flow anywhere from 25,000 /125,000 Btu's

(Model 125) and 25,000/77,500 (Model 80).

Special “S” version heaters have the ability to further

modulate gas flow so that the effective output approaches

0. This permits the AquaStar 80/125 vpS to work

effectively and safely with pre-heated water.