13

valve discharges by itself, a problem exists and

service is required. This could be due to a de-

fective relief valve or to overheating.

Pilot Flame: The pilot flame should burn with

a clean sharp blue flame and should resemble

Fig.4 below. If the flame is yellow, or if the

central button Fig. 2 (P) has to remain de-

pressed for a long time in order to keep the pilot

lighted, the pilot may need to be cleaned or the

orifice replaced.

Fig. 4

Characteristic Pilot Flame

To clean the pilot:Turn off the gas at the unit

Fig. 2 (L). Remove the front panel (unscrew

screws at bottom of corners of front panel, pull

out and lift panel off). Disconnect the Pilot Tube

Fig. 2 (S) at its base and blow gently through it

(

see diagram of Pilot Assembly, page 19). Be

careful not to lose the pilot orifice and

washers. Remove and clean pilot filter by

peeling off the outer layer. Do not use any wire

or sharp object to clean orifices. Natural gas

orifices are large enough that you can usually

clean them by blowing through them. LP orifices

are too small to clean and should be replaced.

Do not enlarge the orifice.

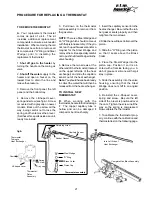

Main Burner Flames: The main burner flames

should be blue, with a more intense blue cone in

the center core.

Compare with Fig 5 in opposite

column. Yellow flames could be a sign of wrong

size gas orifices or dirty burners. If some burn-

ers have yellow flames while others have good

flames, it is likely that dust, lint or spider webs

have partially clogged the burner venturi.

Wash the stainless steel burners if they are dirty.

Burners can be detached from the heater by re-

moving the pilot tube and the thermocouple as-

sembly and disconnecting the Energy-Cut-Off.

(Do not lose the retaining clip) The burners

are secured to the main frame by two screws on

either side. Do not remove the five screws across

the front of the burner assembly. Also examine

heat exchanger fins for dirt. Brush and vacuum if

dirty. Burnt edges at the bottom of the heat ex-

changer shroud are a sign of inadequate air sup-

ply, poor venting or some other combustion prob-

lem. The cause of this situation must be corrected:

contact your installer, service agency or the gas

supplier.

WARNING: Accumulation of dust and lint on

the heat exchanger fins will reduce air flow

and could cause corrosion of the copper

heat exchanger. Keep the appliance area clean

and free from combustible materials, gasoline and

other flammable liquids and vapors. Do not ob-

struct the flow of combustion air and ventilation

air. If installed near a dryer, make sure the dryer

is properly vented, and that the AquaStar vents

properly when the dryer is operating.

Fig 5.

Characteristic Burner Flame Pattern

- to thermocouple

to burners -