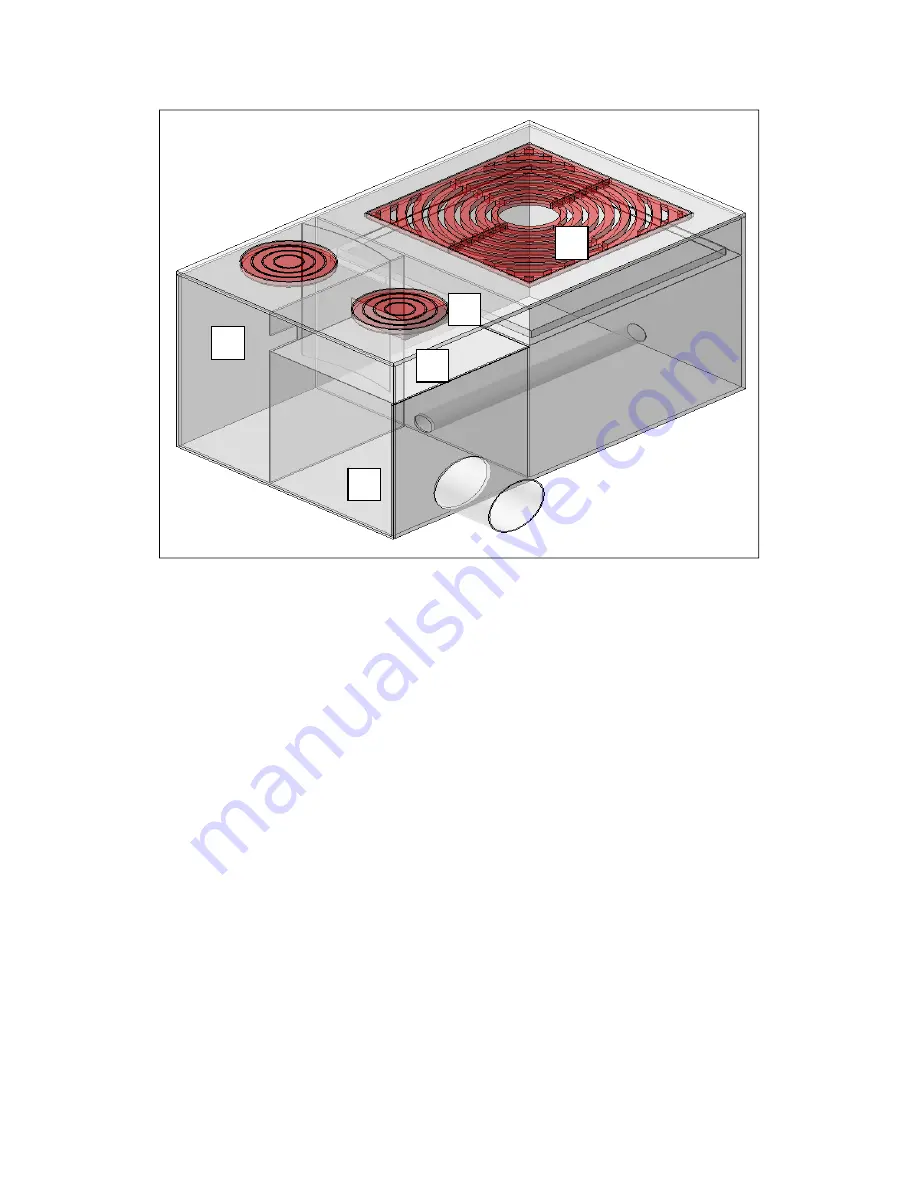

Figure 1. AquaShield

TM

Bio-Filter

TM

System and its five design elements

Step 2: Pretreatment

The water quality treatment flow enters the Pretreatment Chamber where coarse

sediment and oil are captured and retained by principles associated with

hydrodynamic vortex separation, such as that incorporated into the design of the

field proven Aqua-Swirl

®

Stormwater Treatment System. Water enters the

Pretreatment Chamber by a tangential inlet between the Trash Shelf and

Pretreatment Chamber. This inlet sets up the swirling flow motion forcing coarse

sediment to fall out of suspension and accumulate at the base of the chamber.

Any floatables and oil will be retained by the arched baffle positioned on the

outlet side of the chamber. Water exits the Pretreatment Chamber underneath

the arched baffle and through a horizontal opening that extends along the width

of the chamber wall. Water then enters the Biofiltration Chamber.

Step 3. Biofiltration

The water quality treatment flow is distributed across the entire top of the

Biofiltration Chamber via a flow distribution channel that extends entirely along

the outer edge of the chamber. The distribution channel also dissipates the water

flow’s energy to avoid disturbing the engineered soil biomedia and tree. Water

then flows downward driven by gravity flow through the biomedia and plant root

ball to remove fine sediment, heavy metals, residual oil and phosphorus. Next,

1

2

3

4

5