TABLE OF CONTENTS

Page

SECTION I.

INTRODUCTION ...................................................................................3

SECTION II.

SPECIFICATIONS ................................................................................4

SECTION III.

PREPARATION .....................................................................................5

A. Major System Components .............................................................

5

B. Tools Recommended for Installation ...............................................

7

C. Site Selection For Major System Components ...............................

7

SECTION IV.

INSTALLATION STEPS ........................................................................8

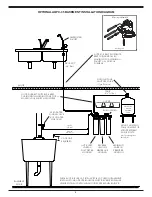

A. Faucet

Installation

...................................................................................

8

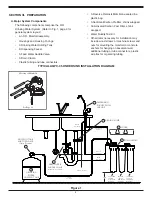

B. Feed Water Saddle Valve Installation ...........................................

10

C. Drain Clamp Installation ................................................................

10

D. R.O. Manifold Assembly Installation .............................................

11

E. Position the Drinking Water Holding Tank

and Make the Final Hose Connections .........................................

12

F. Start Up .........................................................................................

12

SECTION V.

OPERATION AND MAINTENANCE ...................................................12

A. Normal Operation ..........................................................................

12

B. Changing Filters ............................................................................13

SECTION VI.

TROUBLE SHOOTING GUIDE ...........................................................14

EXPLODED VIEW AND PARTS LIST ..................................................................................16

CAUTION:

The Centers for Disease Control and Prevention (CDC) and the Environmental Protection Agency (EPA) have issued guidance to people with severely

weakened immune systems who may want to take extra precautions to reduce the risk of infection with Cryptosporidium from drinking water. This

guidance pertains to people with HIV/AIDS, patients receiving treatment for cancer, recipients of organ or bone marrow transplants, transplant patients

taking immunosuppressive drugs, and persons who have congenital immunodeficiencies.

The EPA has stated that they do not know the significance of drinking water compared to other possible sources of Cryptosporidium to determine how

most people become infected. The CDC-EPA guidance suggests that immunosuppressed individuals discuss their risks with their health care provider.

This drinking water system is tested and Certified by NSF International to NSF/ANSI Standard 58 for cyst reduction. It meets the NSF/ANSI standard of

reducing at least 99.95%* of cysts (including Cryptosporidium), however, because this is not 100%, immunosuppressed individuals should take the extra

precaution of boiling their drinking water. According to the CDC-EPA, bringing water to a rolling boil for one minute is the most certain approach for killing

Cryptosporidium.

All individuals should take adequate precautions when changing the filter cartridges, including wearing protective gloves, to avoid direct contact with the

exhausted cartridges.

*For complete specifications, refer to the Performance Data Sheet.

Summary of Contents for AQPC-35

Page 18: ...18 NOTES...

Page 19: ...19 NOTES...