LUBRICATED PLUG VALVES - SAPM/SAPL

Australian Pipeline Valve - Installation, Operation and Maintenance Manual

20

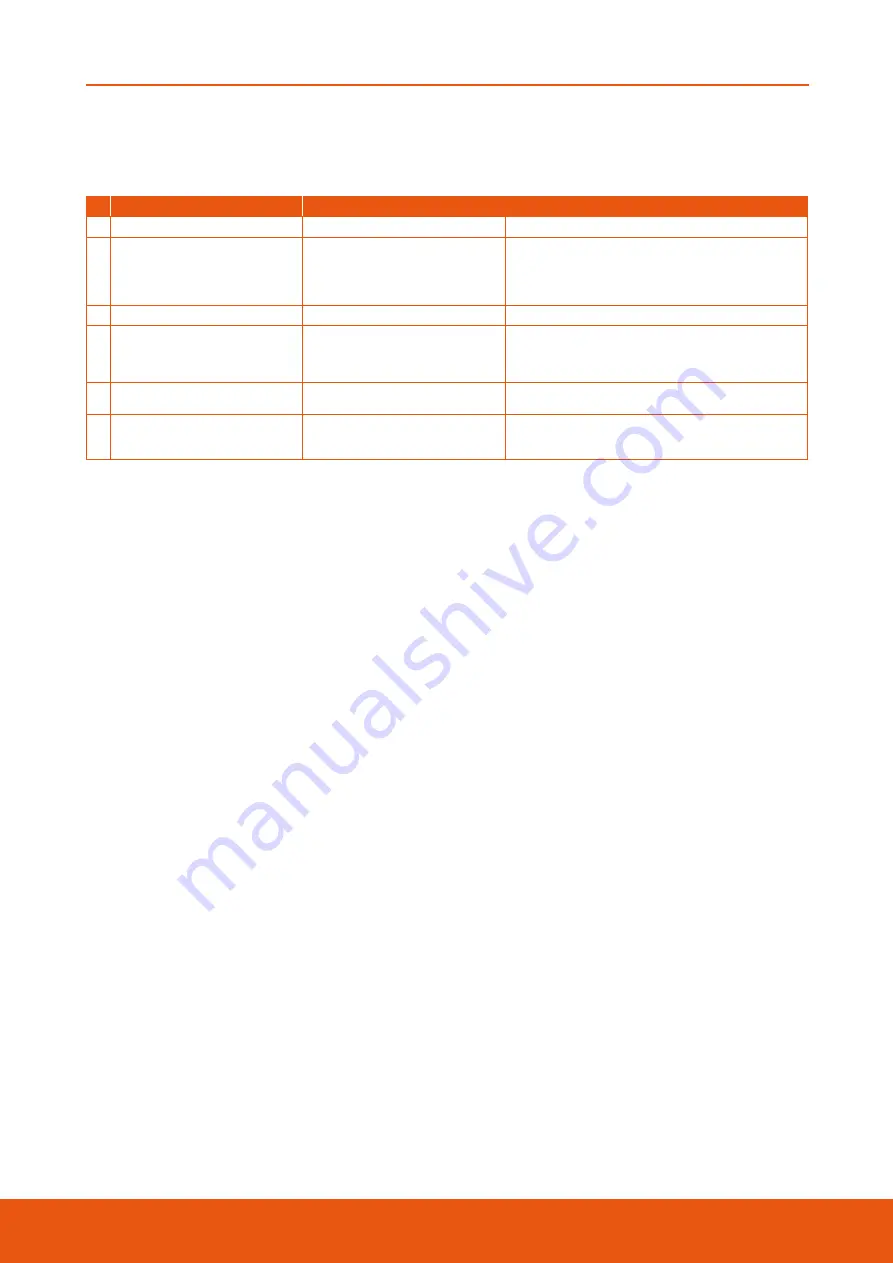

TABLE 4

Trouble shooting guide

TROUBLE

PROBABLE CAUSE

REMEDY

A Won’t fully open or close

Improper setting of gear operator stops

Reset stops for proper installation

B Difficult to operate

1. Sealant level low

2. Dried out sealant

3. Temperature too low

4. Damaged gear operator

1. Inject sealant

2. Flush the valve with valve flush. Follow APV’s instructions

3. Inject low temperature sealant and/or insulate. Consult APV

for recommended sealant

4. Consult APV

C Stem leakage

Yoke not tight

Adjust gland and then inject sealant

D Leaks from seat

1. Sealant level low

2. Plug set incorrectly

3. Incorrect sealant

4. Damaged seats

1. Inject sealant

2. Adjust gland and then inject sealant

3. Consult APV with service details

4. Consult APV

E Leaks through balance hole in the plug 1. Loose sealant check valve

2. Ball check not seated or damaged

1. Inject sealant to clean and reseal check valve

2. Remove from pressure and tighten or replace check valve

F Balance leakage at cover

1. Damaged cover seal

2. Bonnet bolting loose - if this does not

reseal cover, the suspect

1. Tighten cover bolts

2. Remove from service and consult APV

6 . 0 G E A R B O X R E - L U B R I C AT I O N

The gear unit is factory pre-lubricated and does not require lubrication. Where grease nipples are fitted

(much larger sizes) then they can be lubricated through the grease nipples once every 24 months.

However, most types of gear operator do not need any lubrication for their entire life. The gear teeth

racks on worms and wheels do not normally require re lubrication. However, if operation becomes

difficult of noisy, this indicates a lack of lubrication. In this case, re-lubrication is recommended.

The procedure is as follows:

1. Remove the gear cover to access gearbox internals.

2. The lubricant is applied to all tooth racks in a layer of about 1 mm.