Australian Pipeline Valve - Installation, Operation and Maintenance Manual

17

LUBRICATED PLUG VALVES - SAPM/SAPL

smaller size and lower pressure plug valves, ‘packing sticks’ are used and can be screwed in through the

top of the stem with a bolt in lieu of using a grease fitting. If there is no body grease fitting, then the

sealant channel on top of the stem supplies sealant to the plug and the seat. Bolted style gland packed

valves do usually (optionally in smaller sizes) have a separate stem sealant injector but this is only needed

in an emergency to temporarily seal a damaged stem seal (refer to Appendix B and C).

The purpose of lubrication is for 3 reasons:-

- To protect the surface seal of the valve from corrosion and abrasion.

- To contribute to a good seal.

- To contribute to an easy action.

The frequency of re-lubrication depends upon the operating conditions from the required mode of

sealing. Generally the valve should be regreased every 3 or 4 operations of the valve especially if used

high pressure gas however it depends entirely on the period between each operation of the valve.

The following tables gives you the minimum frequency of re-lubrication according to the temperature

range and service type. ANSI class 600 and above should be greased more frequency especially if the

media is high pressure gas. Special grease should be used for low and high temperature.

The quantity of grease for re-lubrication also depends on the operating conditions, however the usual

amount is about 2 gr/mm of passage.

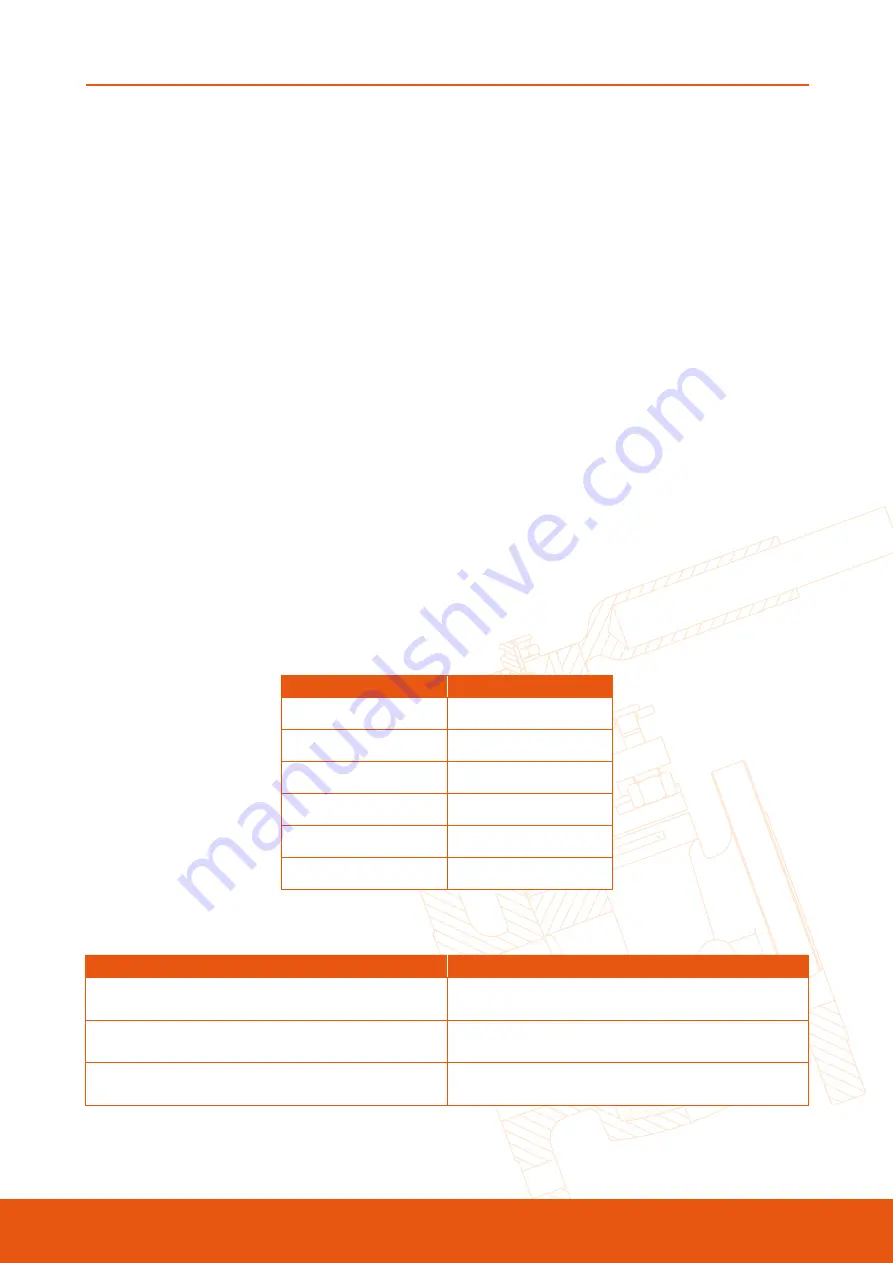

TABLE 1

Frequency of lubrication using temperature as a guide

TEMPERATURE RANGE TEMPERATURE RANGE

-28º to -1ºC

6 months

0º to 100ºC

12 months

-50º to 29ºC

6 months

100º to 150ºC

3 months

150º to 180ºC

2 months

over 180ºC

1 month

TABLE 2

Frequency of lubrication using service as a guide

SPECIAL CONDITIONS

FREQUENCY OF SEALANT INJECTIONS

Infrequent operation, valve either fully opened or fully

closed. Non abrasive gases or liquids.

Every 20 operations, minimum once per year. But,

depends on media, temperature, etc.

Infrequent operation, valve either fully opened or fully

closed. Abrasive gases or liquids.

Every 10 operations, minimum 5 times a year. But,

depends on media, temperature, etc.

Throttling services and abrasive slurries.

Every 5 operations, minimum 12 times a year. But,

depends on media, temperature, etc.