-5-

Getting Started

To use your Applied Motion Products motor control, you will need the following:

• a 12-35 volt DC power supply for the motor. Please read the section entitled

Choosing a Power Supply for help in choosing the right power supply.

• a compatible step motor.

• a small flat blade screwdriver for tightening the connectors (included with drive).

• a personal computer running Microsoft Windows 95, 98, NT, Me, 2000 or XP.

• Applied Motion's eXposition™ software (supplied with drive on CD)

• Applied Motion Si™ programming cable.

If you plan to use the drive in Pulse & Direction Mode:

• a source of step pulses. Signal may be sinking (NPN), sourcing (PNP) or

differential.

• if your application calls for bidirectional rotation, you'll also need a direction

signal. This signal may also be sourcing, sinking or differential.

For Oscillator Mode:

• A run/stop signal or switch and a direction signal or switch. Signals may be

sinking (NPN), sourcing (PNP) or differential.

• Analog speed signal or speed control potentiometer (optional)

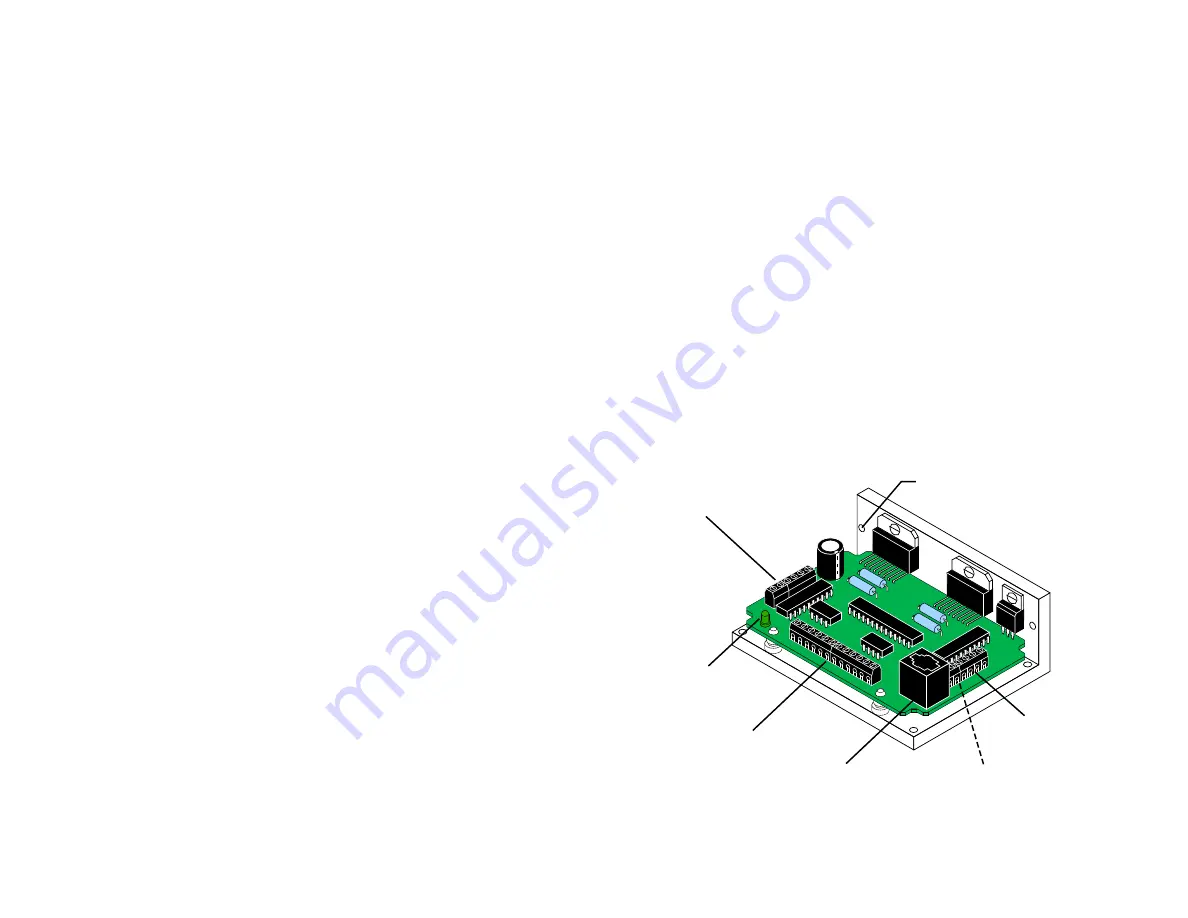

connector

• DC power supply

• motor 1

mounting hole (1 of 6)

pc

connector

for programming

power

LED

connector

• output

• motor 2

connector

• step/run1, dir1

• step/run2, dir2

• analog in1

• analog in2

Always use the blue & white Applied

Motion screwdriver to tighten the

screw terminal connectors. Larger

screwdrivers may remove the plastic

dimples that prevent the screws from

falling out.

-12-

Microstepping

Many step motor drives offer a choice between full step and half step resolutions.

In most full step drives, both motor phases are used all the time. Half stepping

divides each step into two smaller steps by alternating between both phases on and

one phase on. Microstepping drives like the 2035XD precisely control the amount

of current in each phase at each step position as a means of electronically subdivid-

ing the steps even further. The 2035XD offers a choice of full step, half step and 13

microstep resolutions. The highest setting divides each full step into 254

microsteps, providing 50,800 steps per revolution when using a 1.8° motor.

In addition to providing precise positioning and smooth motion, microstep drives

can be used to provide motion in convenient units. When the drive is set to 2000

steps/rev (1/10 step) and used with a 5 pitch lead screw, you get .0001 inches/step.

The step resolution is selected using the eXpositon™ software on your PC.

Restrictions

Restrictions

Restrictions

Restrictions

Restrictions:

If an axis is in run/stop mode, the resolution of that axis is automatically 12,800

steps/rev.

If one axis is set for full step (200 steps/rev) or half step (400 steps/rev) then the

other axis must be also set for 200 or 400 steps/rev.

Direction signal must be set at least 10 microseconds before activating the run

signal, or the move may take place in the wrong direction.

SHOP ONLINE at www.airlinehyd.com

800-999-7378