10

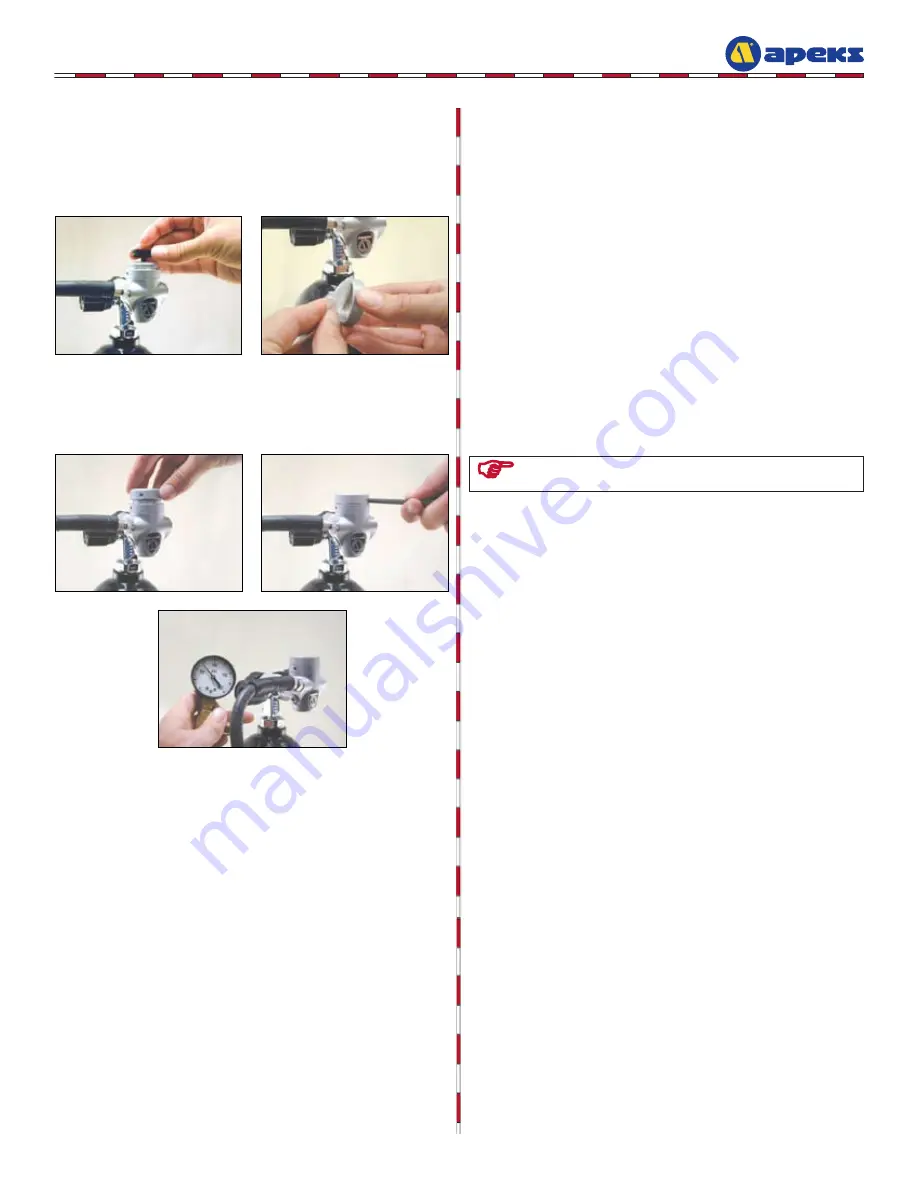

1. With the first stage still pressurized,

insert the hydrostatic

transmitter (4) into the dry chamber. Press the hydrostatic

diaphragm () into the end cap (1).

. Thread the end cap (1) onto the dry chamber until hand tight.

Using the pin spanner (pn AT0), tighten the end cap until

snug. Recheck the MP to confirm it has not changed.

. Close the cylinder valve and depressurize the regulator. Re-

move the test gauge and reinstall the blanking plug.

FINAL ASSEMBLY

NOTE: Do not confuse bubbles from trapped air with a true leak. If

there is an air leak, bubbles will come out in a constant stream.

. Assuming there are no leaks, close the cylinder valve and

depressurize the regulator. Remove the first stage from the

cylinder valve and secure the dust cap in place.

THIS CONCLUDES THE SERVICE PROCEDURES

FOR THE FSR/FST FIRST STAGE.

External Leak Test

1.

After disconnecting the MP test gauge from the first stage,

connect the first stage to a scuba cylinder filled to approxi

-

mately 000 psi (06 bar). Slowly open the cylinder valve to

pressurize the regulator and submerge the entire system in a

test tank of clean water.

. Observe any bubbles arising from the submerged regulator

over a one minute period. The recommended time is neces-

sary due to slower bubble formation that occurs in smaller

leaks. Bubbles indicate a leak, this would require the system

to be disassembled at the source to check sealing surfaces,

assembly sequence and component positioning in order to cor-

rect the problem(s). If any bubbles are visible, refer to

Table

1: Troubleshooting Guide, p. 11.

FINAL TESTING PROCEDURES