Safety warning

Maintenance

1.

Read the operating instruction carefully before installing and using the device.

2.

The whole equipment must be reliably grounded with a grounding resistance of less than 1 ohms during use; Otherwise, it is easy to

cause abnormal or even damage of ion bar.

3.

Do not use the device when the humidity is higher than 70%.

4.

Do not use the device in inflammable and explosive environment.

5.

It is strictly forbidden to disassemble products without authorization. Internal maintenance and repair must be carried out by

professional personnel.

6. The product is strictly prohibited to touch liquid during use

, otherwise there will be abnormal, resulting in electric shock or fire.

7.

Power must be turned off during inspecting or replacing the product, otherwise it may cause electric shock or fire.

8.

The product is specially designed for removing static electricity and is strictly prohibited for other purposes. Any abnormal use may

cause machine failure, electric shock, fire and other hidden dangers.

9.

It is strictly forbidden to touch the electrode needles when power is on, otherwise it is easy to cause fault and electric shock accident.

10.

Discharge needle is a sharp metal object, please use it with care.

11.

Please check the specifications of the power supply before powering on the product. Any power supply that does not meet the

specifications may cause damage or even failure to the product.

12.

Check the power cord regularly. If it is damaged, replace it immediately; otherwise, leakage and abnormal operation may occur.

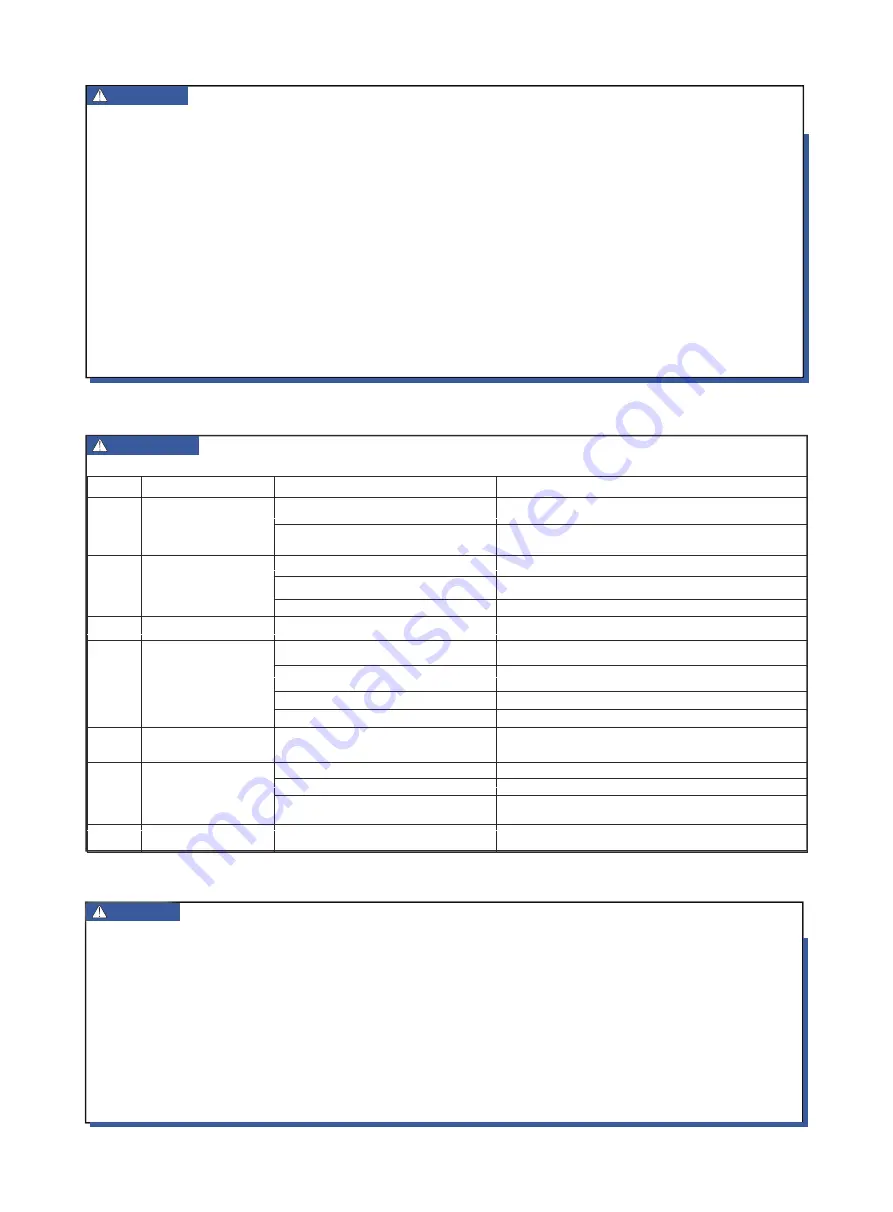

NO.

1

The indicator on the

panel is off

Confirm the power supply specification

(

INPUT

:

100—240VAC

50/60Hz

;

OUTPUT

:

24VDC 2000mA

)

2

Whether the discharge seat is tightened

Confirm the discharge seat is tightened

3

4

Panel indicator red light on

Confirm the installation location and stay away from

surrounding conductors

Return to factory for maintenance

Return to factory for maintenance

5

Panel indicator blue light

flashes

Poor grounding of the strip grounding electrodes

on both sides of the electrode needle at the

bottom of the ion bar

Return to factory for maintenance

6

Return to factory for maintenance

Return to factory for maintenance

Main-board chip is damaged caused by poor

grounding or no grounding

7

High voltage module is damaged or insulation

of the discharge seat is damaged

Return to factory for maintenance

7URXEOHVKRRWLQJ

Problems

Reasons

Solutions

The electrostatic removal

performance decreased

obviously

The electrostatic removal

performance decreased

Unable to discharge

The product is smoky or burnt

Poor contact of the power cable

Power supply mismatch

Discharge needle is polluted and damaged

Bearing set

of ion bar is improper

There are conductors or other

ion bar

around

Electromagnetic interference

Abnormal discharge

No power supply for high voltage module

High voltage module is damaged

High voltage module is damaged

Main-board chip is damaged

Check whether the power cable is in good condition and

securely connected

Clean or replace the discharge needle

Confirm the best bearing

set

Remove (moving) conductors or other

ion bar

Turn off the power switch / unplug the power cable, restart

the ion

bar

Check the grounding of the

ion bar

and plant equipment, and return

to the factory for maintenance

1.

The ion bar should be cleaned and maintained in time according to the use environment and the required electrostatic protection

requirements in order to ensure the good performance of the product. That is, gently remove the carbon deposits on the discharge

electrode, discharge socket, and metal discharge body with electrostatic brush, dust-free cotton swab, dust-free cloth dipped in

anhydrous alcohol, which will improve its performance significantly. Note:

A.

Operation must be done 10 minutes after power cut of

f.

B.

It must be cleaned when dust or white

stuff

appear on the tip of the needle during use. Use dust-free cloth dipped in anhydrous

alcohol to clean when brush can not meet the cleaning requirements.

C.

The ion bar must be powered on after alcohol is completely volatilized after cleaning. No other organic solvent can be used to clean

the ion bar.

2.

If the switch working indicator light of the power plug-in port on the panel of the ion bar is off , it should be stopped and repaired by

professional maintenance personnel. It can be used only after the electrical performance index is normal.