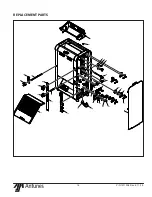

20

P/N 1011308 Rev. E 11/16

Item Part No.

Description

Qty.

Item Part No.

Description

Qty.

Item Part No.

Description

Qty.

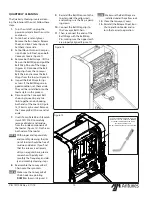

REPLACEMENT PARTS (CONTINUED)

1

0012472

Inner Spring Tensioner Assy.

4

2

0012982

Conveyor Belt Assembly 37/2

2

3

0012988

Tensioner Assembly

4

4

0012989

Bun Feeder Assembly

1

5

0012990

Conveyor Cover Assembly

2

6

0021900

Idle Bearing Retainer Weldment

1

(Incl. with kit 7001115 - Item 100)

7

0021959

Cam Weldment

2

8

0021960

Base Weldment

1

9

0021962

Control Panel Weldment

2

10

0021964

End Housing Weldment

1

11

0021965

Control Housing Weldment

1

12

0022040

Bun Chute Weldment

1

13

7000780

Platen, Grill 120V/1800W

1

14

0400147

Bushing, Shorty 7/8”

1

15

0400265

Bushing, Shorty 3/8”

4

16

0400437

Strain Relief, Rt Angle

1

17

0500464

Bearing Retainer

1

18

0503495

Bracket, Retainer Right

2

19

0503496

Bracket, Tensioner-Right

2

20

0503497

Bracket, Tensioner-Left

2

21

0503507

Bracket, Retainer Left

2

22

0506755

Retainer, Bearing

6

23

0506756

Plate, Motor

1

24

0507179

Panel, Electrical

1

25

0507180

Bracket, Trx-Hi-Limit

1

26

0700925

Power Cord Right Angle

1

27

0800455

Rod, Knob (Heel)

1

28

0800457

Rod, Knob (Crown)

1

29

0800458

Rod, Support

4

30

0800460

Shaft, Drive

2

31

0800461

Shaft, Idler

2

32

1000900

Label - Warning

1

33

1001181

Label, Crown

2

34

1001527

Label, Roundup Service

1

35

1001550

Label, Control

1

36

1001551

Label, Install

1

37

1001552

Label, Cam (Heel)

1

38

1001553

Label, Cam (Crown)

1

39

1001556

Label, Wiring Diagram

1

40

1001592

Label, Chain Tensioning

1

41

1031188

Spec Label

2

42

2100230

Bumper, Recess W/Washer

4

43

2100348

Knob, 1/4” Shaft, Push-On

2

44

2110127

Ring, Retaining

8

45

2120107

Spacer, Aluminum

2

46

2120147

Spacer, Leg

4

47

7000296

Ball Bearing Kit (2-Pak)

1

48

2150173

Sprocket, 25B12 3/8” Bore

1

49

2150179

Sprocket, 25B14 1/2” Bore

3

(1 Incl. with kit 7001115 - Item 100)

50

7000224

Bearing & Retainer Kit

1

51

7000207

Sprocket Kit, 25B28 x 1/2”

Bore Stepped Tooth

1

52

2150258

Bearing, Idler

1

(Incl. with kit 7001115 - Item 100)

53

2150260

Spacer, Bearing

6

54

2150368

Miter Gear, 20° Pressure Angle

4

55

2150370

Chain, Drive

1

56

2180145

Cover, Bumper

4

57

3000124

Ring, Retaining 3/8”

1

(Incl. with kit 7001115 - Item 100)

58

304P105*

Nut, Hex ‘Keps’ #4-40

2

59

306P121*

Screw, Mach #6-32 X 3/4”

2

60

306P123*

Screw, Mach #6-32 X 7/8” Slrndhd

4

61

306P130*

Nut, Hex Keps #6-32 (Small Pattern)

8

62

306P156*

Screw, Mach. #6-32 X 1/2”

2

63

308P115*

Screw, Mach. #8-32 X 3/8”

8

64

308P143*

Nut, Hex ‘Keps’ #8-32

8

65

308P144*

Screw, #8-32 X 1/4” (#6 Head)

16

66

308P157*

Screw, Tap 8-32 X 3/8”Lg

4

67

308P203*

Screw, Tap 8-32 X 3/8”

26

W/Int. Tooth Washer

68

310P103*

Screw, Mach. #10-32 X 1/4”

4

69

310P136*

Screw, Mach. #10-32 X 1/4”

4

70

310P146*

Nut, Hex ‘Keps’ #10-32

24

71

310P213*

Screw, Phpnhd #10-16 X 3/4” Thrd Form 4

72

325P104*

Washer, Flat 1/4” S/S

4

73

325P163*

Set Screw, 1/4-28 X 5/16”

8

74

325P203*

Washer, Spring Steel Single-Wave

8

75

3380116

Screw, Shoulder

4

3/8-16 X 3/8 W/ 1/2 Shoulder

76

7001375

Drive Motor Kit 120V

1

77

4000210

Fan, Axial 115V

1

78

4010199

Transformer, 120 Vac/12Vac

1

79

7000882

Power Switch Repl. Kit

1

80

4030332

Thermostat, Hi-Limit

1

81

4050214

Thermocouple Type “K” (Open End)

1

82

4051010

Relay, Random Phase, Solid State-50A 1

83

4060234

Wire Strap - 3/7”

1

84

4060303

Bus Bar Contact 3-Pole

2

85

4060355

Terminal Block, 3-Pole

3

86

7001005

Control Board Kit

1

87

4070213

Varistor Board

1

88

7000985

Black Wavy Silicone Belt

1

89

0021961

Conveyor Cover Weldment

2

90 0502199 Spacer

4

91

0011311

Roller Tensioner Assembly

2

92

308P145*

Nut, Hex Acorn #09-32

4

Low Crown; S/S T304

93

308P102*

Washer, Int. Tooth #09 Steel; Zinc Plated 4

94

0505968

Spring, Inner Tensioner

4

95

7000780

Rail, Slide Kit (Small)

1

96

308P181*

Screw, Mach. #8-32 X 3/8” Lg

4

Phflthd, 18-8 S/S Brt

97

7000779

Rail, Slide Kit (Large)

1

98

7000989

Sheet, Platen (Pk of 2)

1

99

7001084

Cleaning Tool Kit - VCT-2

1

100 7001115

Idler Sprocket Replacement Kit

1

*Available in Packages of 10 (ten).