®

P/N 1010455 Rev. K 10/20

6

THIS UNIT IS DESIGNED TO

OPERATE

ON 208 VOLTS

ONLY

. APPLICATION WITH ANY

OTHER VOLTAGE SUPPLY

COMPLETELY

VOIDS ALL

WARRANTY

. PLEASE CHECK

YOUR LINE VOLTAGE BEFORE

INSERTING THIS PLUG INTO THE

RECEPTACLE.

W

WAARRNNIINNGG

W

WAARRNNIINNGG

THIS UNIT IS DESIGNED TO

OPERATE

ON 120 VOLTS

ONLY

. APPLICATION WITH ANY

OTHER VOLTAGE SUPPLY

COMPLETELY

VOIDS ALL

WARRANTY

. PLEASE CHECK

YOUR LINE VOLTAGE BEFORE

INSERTING THIS PLUG INTO THE

RECEPTACLE.

W

WAARRNNIINNGG

W

WAARRNNIINNGG

120 VAC

ONLY

208 VAC

ONLY

TTHHIISS AAPPPPLLIIAANNCCEE M

MUUSSTT BBEE

EEAARRTTHHEEDD ((GGRROOUUNNDDEEDD))

TTHHIISS AAPPPPLLIIAANNCCEE M

MUUSSTT BBEE

EEAARRTTHHEEDD ((GGRROOUUNNDDEEDD))

TTHHIISS AAPPPPLLIIAANNCCEE M

MUUSSTT BBEE

EEAARRTTHHEEDD ((GGRROOUUNNDDEEDD))

TTHHIISS AAPPPPLLIIAANNCCEE M

MUUSSTT BBEE

EEAARRTTHHEEDD ((GGRROOUUNNDDEEDD))

THIS UNIT IS DESIGNED TO

OPERATE

ON 220-240 VOLTS

ONLY

. APPLICATION WITH ANY

OTHER VOLTAGE SUPPLY

COMPLETELY

VOIDS ALL

WARRANTY

. PLEASE CHECK

YOUR LINE VOLTAGE BEFORE

INSERTING THIS PLUG INTO THE

RECEPTACLE.

W

WAARRNNIINNGG

W

WAARRNNIINNGG

220-240

VAC ONLY

TTHHIISS AAPPPPLLIIAANNCCEE M

MUUSSTT BBEE

EEAARRTTHHEEDD ((GGRROOUUNNDDEEDD))

TTHHIISS AAPPPPLLIIAANNCCEE M

MUUSSTT BBEE

EEAARRTTHHEEDD ((GGRROOUUNNDDEEDD))

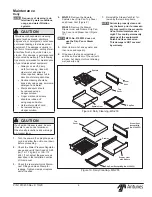

Electrical

1.

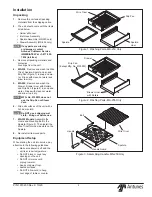

Place the unit on a sturdy, level table

or other work surface.

2.

Ensure that the line voltage corre-

sponds to the stated voltage on the

units specification label and power

cord warning tag.

If you are unsure

of your Line Voltage, contact an

electrician.

3.

Connect the unit to the power supply.

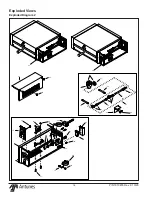

Figure 4. Connecting Water Supply

Plumbing

NOTE:

Miracle Steamer models are

designed to use cold tap water.

Distilled water may be used

to reduce calcium/mineral

deposit buildup and reduce

maintenance costs.

These units require a direct cold water

hookup. A Water Inlet Hose and Strainer

Assembly (Figure 4) is supplied.

NOTE:

Incoming water is controlled

by a normally closed (NC) sole-

noid valve located inside the

Steamer’s electrical housing.

1.

Turn off the water valve (not sup

-

plied) that supplies water to the unit

(Figure 4).

2.

Connect the 1/4” (6.5 mm) I.D.

Flexible Tubing to the outlet side

of the Water Pressure Regulator

and secure using the Worm Clamp

(Figure 4).

NOTE:

A Water Pressure Regulator

must first be installed (Figure

4). Failure to do so will result

in poor steaming and possible

flooding. For a single steamer,

use Water Pressure Regulator

P/N 7000314. For two adjacent

steamers, use Water Pressure

Regulator P/N 7000235. For

Mfg. No. 9100933 use only P/N

0012001.

3.

Turn the water valve on.

4.

Hold the Quick Disconnect Insert

over a bucket, then press and hold

the white plastic tip until there’s a

good, steady water flow. This will

purge all air out of the line.

5.

Release the plastic tip and check

the pressure on the Water Pressure

Regulator. It should read

20 psi.

a.

If it reads less, increase the

water pressure by pulling the

black knob up and turning it

clockwise.

b.

If it reads more, decrease the

water pressure by pulling the

black knob up and turning it

counter clockwise.

NOTE:

When adjusting the knob,

relieve the existing pressure by

pressing the plastic tip on the

Quick Disconnect Insert for 3

seconds. The Water Pressure

Regulator will then show the

new pressure.

3.

Once the regulator reads 20 psi,

push the black knob down to lock it

in place.

4.

Push the Quick Disconnect Insert

into the fitting at the rear of the unit

until it clicks (Figure 4).

Connect Quick

Disconnect

Insert Here

Inlet Hose & Strainer

Assy. (Supplied)

Optional Water Pressure Regulator

with Strainer (P/N 7000314 shown)

Shut Off Valve

(Not Supplied)

Cold

Water

Flow

Flexible Nylon Braided

1/4 " I.D. Tubing (Not Supplied)

Quick

Disconnect

Insert

Worm

Clamp

NOTE:

The use of only one strainer is

acceptable instead of two.

CAUTION

Water pressure must not exceed 30

psi (2.1 kg/cm2 or 207 kPa). Higher

pressure may cause poor performance

or flooding. To reduce water pressure,

install a Water Pressure Regulator, and

set to 20–25 psi (1.4–1.7 kg/cm2 or

138–172 kPa).

CAUTION

This equipment is to be installed to com-

ply with the basic plumbing code of the

Building Officials and Code Administra

-

tors, Inc. (BOCA) and the Food Service

Sanitation Manual of the Food and Drug

Administration (FDA).