©Copyright Amkus Rescue Systems, Inc. 2010-2020

LAP-005 JUNE 22, 2020 Rev05

Important Safety Instructions

Safety

It is the responsibility of the user to insure that appropriate

protective clothing and equipment are used to provide

protection from those hazards to which personnel are

exposed or could be exposed while working with this

product.

Always wear appropriate apparel!

AMKUS equipment is manufactured with superior

craftsmanship and quality that is backed by a factory

warranty. AMKUS cannot control how other manufacturers

of rescue tools rate, test and warranty their equipment.

Therefore, we do not recommend that tools other than

AMKUS be connected to our equipment. Mixing AMKUS

equipment with another manufacturer’s equipment may

cause operational problems, equipment failure or warranty

claims to be denied.

Use only AMKUS supplied

mineral base hydraulic

fluid in all AMKUS equipment.

Training

This product is designed to be used by emergency services

personnel to facilitate the extrication of victims from

entrapment. Its use should be limited to trained personnel

only. All personnel using this equipment are assumed to

have completed a course of instruction that is acknowledged

as being educationally sound by the local authority having

jurisdiction over such training. This document contains

basic operating and maintenance instructions only.

Getting Started

1. Connect the tool connection hoses to the hose lines from

the AMKUS hydraulic power unit. Please note that the

male and female couplings on the hose lines leading from

the power unit should be connected to the corresponding

male and female couplings on the tool connection hoses.

To connect the couplings, twist the sleeve on the female

coupling so that the notch in the sleeve lines up with the

pin. Push the sleeve back so the pin fits into the notch.

While holding the sleeve back, push the male coupling

into the female coupling. Release the sleeve; it will spring

forward into place. Twist the sleeve ¼ turn so that the pin

no longer lines up with the notch. Pull on the couplings to

check that they are securely connected.

2. Check the engine oil, engine fuel and hydraulic fluid

levels. Add as appropriate.

Read and understand the

engine owner’s manual

before operating the engine! Failure to do so

could result in personal injury or equipment

damage!

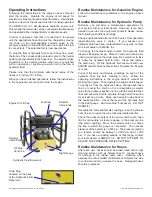

Set-Up Procedures

Normally, AMKUS equipment is prepared and serviced by

your dealer prior to delivery. If, however, you have decided

to place the equipment into service yourself, please review

the following instructions carefully.

1. Remove equipment from the packing cartons and

carefully inspect for damage. Damage that occurs during

shipment should be reported immediately to the carrier.

2. The Briggs and Stratton

®

engine that powers your unit is

shipped without engine oil. Fill the engine crankcase with

the proper oil as specified in the engine owner’s manual.

3. Next, remove the hydraulic fluid reservoir fill plug/vent

cap. Fill the hydraulic fluid reservoir with approximately 2.0

gallons U.S. (7.6 liters) of AMKUS mineral base hydraulic

fluid. The fluid should reach a level that fills approximately

1

/

2

of the sight gauge window. Replace the fill plug/vent cap.

4. Following the instructions in the engine owner’s

manual, fill the engine fuel tank with the specified fuel.

Avoid getting dirt or water in the fuel tank. Never use stale

or contaminated gasoline or an oil/gasoline

mixture.

5. This power unit may be supplied either with hydraulic

hoses attached (pump hoses) or with couplings that require

extension hoses. If your unit is equipped with couplings,

attach the extension hoses to the couplings on the power

unit. In either case, connect the male and female couplings

on each of the hydraulic hose line sets, creating a loop.

6. Follow the operating instructions in the engine owner’s

manual for starting the engine. Then operate the engine at

full speed.

7. To purge air from the hydraulic hoses, charge each

hose line by moving the knob on the corresponding selector

valve to the pressure position (in line with the selected hose

line) and allow the fluid to circulate through each hose line

for at least one minute. Move each selector valve back to

the neutral position.

8. Check the level of the hydraulic fluid in the sight gauge.

Add more fluid if necessary. DO NOT OVERFILL.

9. Uncouple the male and female couplings on each

hydraulic hose line set to open the loop that was created

earlier. The power unit is now ready to use.

CAUTION

CAUTION